Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:50 set

Supply Capability:200 set/month

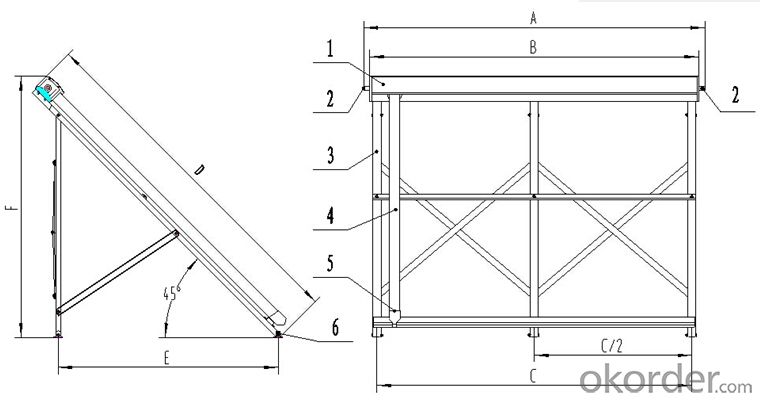

1. Structure of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

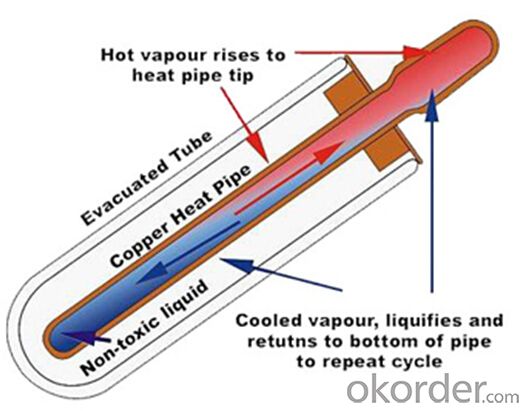

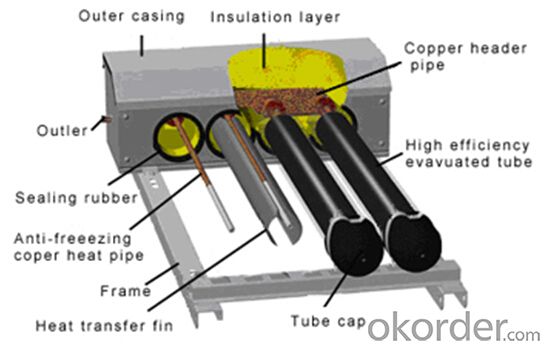

This product is composed of aluminium alloy for frame, polyurethane and aluminium silicate for the insulation,tri-element vacuum glass tube and antifreeze heat pipe. It can work under the environmental temperature from -40℃ to 95℃.The solar collector has the structure as follows:

1,Solar collector manifold :

2,Solar collector connector

3,Solar collector bracket

4,All glass vacuum tube:

5,Tube holder

6,Wind feet

2. Main Features of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

The heat insulation properties is higher than for other types of the same collector design

Three layers of insulation incorporated in the mainfold casing :

(1)first and third layer is Aluminium Silicate and resist temperatures of up to 800℃;

(2)second layer is Polyurethane formed by Italian machine that insulates the tanks with a density of 38.5-42;

3. Polyurethane Foaming Insulation Solar Collector Model SC-HP Images:

4. Polyurethane Foaming Insulation Solar Collector Model SC-HP Specifications

Model | SC-HP-10 | SC-HP-15 | SC-HP-18 | SC-HP-20 | SC-HP-24 | SC-HP-25 | SC-HP-30 |

SC-H1-10 | SC-H1-15 | SC-H1-18 | SC-H1-20 | SC-H1-24 | SC-H1-25 | SC-H1-30 | |

Vacuum tube quantity(pcs) | 10 | 15 | 18 | 20 | 24 | 25 | 30 |

Tube spacing (㎜) | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

Vacuum tube diameter/length (㎜) | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 |

Vacuum tube material | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 |

Vacuum tube inner/outer pipe wall thickness (㎜) | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 |

Heat pipe condensing end diameter/length (㎜) | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 |

heat pipe material/wall thickness (㎜) | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 |

inner tank diameter/wall thickness (㎜) | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 |

connector size | φ22 or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ |

collector insulation material/thickness (㎜) | Polyurethane/40 | Polyurethane/40 | Polyurethane/40 | Polyurethane40 | Polyurethane40 | Polyurethane/40 | Polyurethane/40 |

solar collector rated pressure (MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

collector operating temperature ℃ | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

collector volume (L) | 0.69 | 0.98 | 1.15 | 1.27 | 1.50 | 1.56 | 1.85 |

collector aperture area (㎡) | 1.0 | 1.5 | 1.8 | 2.0 | 2.4 | 2.5 | 3.0 |

collector total area (㎡) | 1.56 | 2.30 | 2.74 | 3.04 | 3.63 | 3.77 | 4.51 |

referral traffic (L/min) | 0.75 | 1.13 | 1.35 | 1.50 | 1.81 | 1.88 | 2.26 |

intensity pressure (Pa) | 23.2 | 59.2 | 90.6 | 116.7 | 181.7 | 200.2 | 314.0 |

intercept efficient η0 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 |

heat loss coefficient a | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 |

collector power (W)1000W/㎡ irradiation | 620 | 870 | 1047 | 1165 | 1401 | 1457 | 1748 |

collector net weight (kg) | 38.25 | 50.75 | 59.75 | 64.75 | 79.00 | 83.35 | 98.70 |

a (㎜) | 895 | 1270 | 1495 | 1645 | 1945 | 2020 | 1395 |

b (㎜) | 800 | 1175 | 1400 | 1550 | 1850 | 1925 | 2300 |

c (㎜) | 725 | 1100 | 1325 | 1475 | 1775 | 1850 | 2225 |

c/2 (㎜) | —— | —— | —— | —— | 887.5 | 925 | 1112.5 |

d (㎜) | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 |

e (㎜) | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 |

f (㎜) | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 |

5. FAQ

(1) Which collector is the best value for money?

Rather than looking at just peak efficiency levels when comparing solar collectors, cost per unit of energy produced is much more logical. For example: Although collector A may be 20% more efficient than collector B, if collector A is 30% more expensive, then in fact collector B may be a better choice, as per kWh of energy produced per day it is cheaper. When payback time is of concern, not only price per kWh of the product is important, but also of the end system.

(2) Can this solar collectors be used for a large scale hot water production?

Yes. This solar collectors can be connected in series or parallel to provide large scale hot water production for a commercial settings such as a school, hotel or office building. There is really no limit to the size of the system, however collectors must be installed in banks of no more than 150 tubes (in series), otherwise the water may boil.

(3) What maintenance of the solar collector is required?

Under normal circumstances no maintenance of the system is required. Due to the shape of the tubes regular rainfall and wind should keep the tubes clean. Should a tube even be broken it should be replaced. This, however, is an inexpensive and easy job. Any "handy" person can install a new tube (while adhering to local health and safety regulations). Sidite solar collectors can operate with several broken tubes, however the efficiency will be reduced slightly.