Packaging & Delivery

| Packaging Details: | 220kg/drum, 4 drums per pallet |

|---|---|

| Delivery Detail: | within seven days after receipt of the payment |

Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

Place of Origin: China (Mainland)

Model Number:DQT-508

| Packaging Details: | 220kg/drum, 4 drums per pallet |

|---|---|

| Delivery Detail: | within seven days after receipt of the payment |

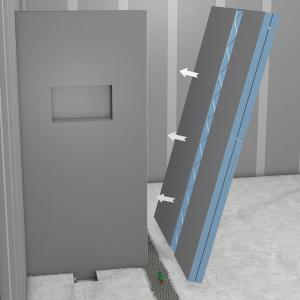

Polyurethane Adhesive for Sandwich Board

DQT-508

Introduction

Polyurethane Adhesive for Sandwich Panels is two components foaming type PU adhesive, with excellent adhesive property, widely used for binding sandwich boards for industrial plants and cold rooms etc. The main characteristics are as follows,

l With absorption and adhesion to different kinds of materials, not only bond porous materials, but also smooth surface materials.

l Excellent cohesive property, formula with good tolerance, which can meet different cohesive properties and technology requirements, the low temperature performance is better than other kinds of adhesive.

l No byproduct produced while cure, will not cause defect on the cohesive surface.

l Excellent mechanical performances, with nice ageing resistance, shock resistance and oil resistance etc.

Typical Properties

| DQT-508 |

Appearance Hydroxyl value mgKOH/g Viscosity mPa.S/20°C Specific gravity g/ml(20°C) Storage Temperature °C Storage Stability month | Brown to yellow transparent liquid 150-250 200-500 1.08 ≤25 6 |

Storage in dry original packing in recommended temperature

Reactivity Properties ( Material temperature: 20°C) Actual value varied as per processing condition

Ratio Cream time S Gel time S Tack free time S | 1:1 5-15 15-45 20-80 |

Typical Foam Performances

Shearing strength Peeling strength Freezing&Thawing resistance | KPa N/cm

| ≥200 ≥30 -15°C12h/25°C12h circle 20 times,no change in adhesive layer |

Attentions

Colored steel plates need to be smooth surface, dry and no greasy dirt and dust. PS foam plates should be same thickness, even texture, the thickness difference is below 1%, surface should be dry, no greasy dirt or dust. If can't meet the requirement above, the cohesive performance will be affected.

Protection

Using the product should comply with normal standards of industrial hygiene, labor protection products need to wear well, to avoid skin, eye contact with materials, when the skin was stained, the application of soap and plenty of water to flush out; If contact with eyes, then the application of low-pressure flow of clean water wash away, if the persistent discomfort, should be invited to the medical treatment.