Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Profile

Pneumatic Girder Gantry Cranes is a kind of gantry crane specially designed for bridge construction. This crane is mainly composed of assembled main beam, outrigger and trolley, the component is connected by hinge pin and high strength bolt, so it is easy to transport and dismounting; Compared with the ordinary gantry crane, installation of pneumatic girder gantry cranes is much more convenient, quickly, and economical.

Function

Two sets of Pneumatic Girder Gantry Cranes can be cooperated to lift prefabricated beams, also can lifting a prefabricated beam with a single crane; lifting capacity of two sets of pneumatic girder gantry cranes separately can reach 450t, and the lifting capacity of single set of pneumatic girder gantry cranes can reach 900t. This crane equip outrigger travelling, trolley travelling and trolley lifting equipment, it can achieve a full range of mechanized movements. Pneumatic girder gantry cranes is mainly used to lift the prefabricated beams from the beam manufacture platform to the beam storage platform, and after the maintenance of the prefabricated beam, it will be hoisted from the storage platform to the beam transport truck. This crane is used as lifting equipment to complete the assembly and dis-assembly of bridge girder erecting machine, it also for erection the low pier of bridge.

Lifting Capacity | Single | t | 450 |

Whole | t | 450+450 | |

Span | m | 38 | |

Lifting Height | m | 30 | |

Double Steel Track Center Distance | mm | 1500 | |

Speed | Hoisting | m/min | 0.05 - 0.5 - 1 |

Trolley Traveling | 0.2 - 2 - 4 | ||

Cart Travelling | 0.5 - 5 - 10 | ||

Electric Hoist | Type | CD16-30D | |

Lifting Capacity | t | 16 | |

Lifting Speed | m/min | 3.5 | |

Travelling Speed | 20 | ||

Lifting Height | m | 28.5 | |

Working Class | A3 | ||

Steel Track | P50, P60 | ||

Maximum Wheel Load | Kn | 360 | |

Working Class | A5 | ||

Total Weight | t | 410 | |

Total Power | Kw | 175 | |

Power Source | 3-phase AC, 50Hz 380V | ||

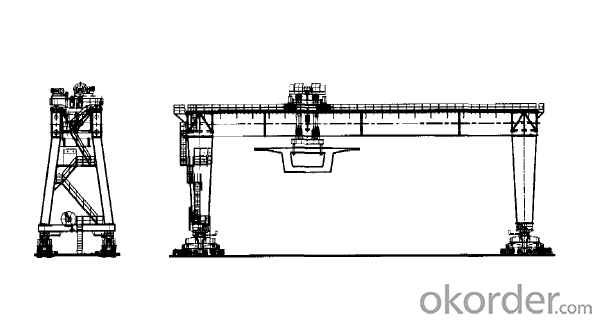

Overall Drawing

Technical Requirements

1. Low speed lifting mechanism and operation mechanism makes concrete box girder counterpoint accuracy, and adopt frequency control regularly for reduce the impact when the concrete box girder and pneumatic girder gantry cranes start braking.

2. The internal clearance of the pneumatic girder gantry cranes should be large enough to meet the needs of assembly and dis-assembly of bridge girder erection machine and transport truck, also need to meet hoisting the concrete box girder to the transport truck.

3. The design of concrete box girder hoisting system to ensure each lifting position of this crane force balanced, avoid the beam bear irregular bending moment and torque in the air.

4. According to the requirements, the strength, rigidity and stability of the main structure should be reduced weight and costs as much as possible.

5. The traveling gear shall adopt a balance device to ensure that each wheel force balanced.

6. When using the double Pneumatic Girder Gantry Cranes to hoist box concrete box girder, it is necessary to meet the requirement of synchronous operation.

Operation and Construction Notice

1. Protection of beam body

- In the process of Pneumatic Girder Gantry Cranes lifting, the lifting points should meet the design requirements and maintain the four fulcrum force balance which in the same plane. The range of error shall meet the design requirements, the hoisting mechanism of trolley realizes the four point lifting and three point balance function through the change of the wire rope winding method.

- Pneumatic Girder Gantry Cranes should doing counterpoint accuracy.

2. Devices of safety precautions

- The inhibiting device is mounted on the limiting position. The whole crane and all parts are mounted inhibiting devices, such as electric limit device and mechanical limit device, which aims to limit the traveling limiting position(horizontal, height and rotation).

- Overload protection measurement. It adopts lifting load limiter which aims to protect the equipment when the lifting mechanism is in overload.

- Scramming measurement. It is used to stop the machine in emergency circumstance. It is made up of professional scramming remote control and scramming buttons which contains to control key points.

- Safeguard procedures of electric system, such as undervoltage, overload, short circuit , earth leakage protection and etc.

- The lifting mechanism is mounted with dual-brake rigging. The hydraulic push rod brake is set on high speed end of transmission mechanism. The hydraulic disk brake is set on low speed end(coiling block).

- The machine and electric adopts interlock which prevent it from incorrect operation. And then it makes use of computer system to filter the incorrect operation.

- The machine is equipped with anemograph, which aims to display the speed condition on operation ground. It can insure that the machine can be operated normally no more than strong breeze.

3. Notes:Operation and maintenance

- After trained and passed the exam, the operator can operate the machine

- The operator should strictly operate the equipment in accordance with operation requirement, operation sequence and operation procedures.

- The operator should check the electric system, hydraulic system and mechanical device regularly.

If any problem has been found, the operator should stop the machine to report.