Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

1. Structure of Multi-Cavities PP Preform Mould

Cavity, core and screw neck of steel adopt imported S136 in Sweden, and be heating treatment of hardness up to HRC48-50.

All moulds base do heat treatment of hardness up to HRC 30-35.

Advanced mould design technology:

a) Each cavity self-locks independently and using high precision JAPAN CNC SYSTEM.

b) To ensure low decent ration & precision of the product.

c) Each mould spare part be inserted with durable parts, which are interchangeable. d) In order to improve and achieve high production efficiency, we always design the best cooling system and can match a cooling machine for each mould.

Advanced & accurate valve hot runner & temperature controller, ensure reliability of production and high transparency & brightness of product.

Mould sliding use copper, bottle be achieved FOOD SECURITY standard, and mould life guarantee more than 3 million shots.

2. Main Features of Multi-Cavities PP Preform Mould

No. of Cavity | 12 Cavity | 16 Cavity | 24 Cavity | 32 Cavity | 48 Cavity | 72 Cavity |

18g(cm) | 60*37*43 | 74*37*43 | 80*50*45 | 76*60*48 | 102*60*55 | 110*86*58 |

Weight(kg) | 625 | 770 | 1300 | 1650 | 2500 | 4100 |

28(cm) | 60*37*45 | 74*37*45 | 80*50*48 | 76*60*52 | 102*60*58 | 110*86*62 |

Weight(kg) | 655 | 810 | 1310 | 1800 | 2690 | 4450 |

40(cm) | 60*37*48 | 74*37*48 | 80*50*50 | 76*60*55 | 102*60*62 | 110*86*65 |

Weight(kg) | 700 | 860 | 1360 | 1900 | 2880 | 4670 |

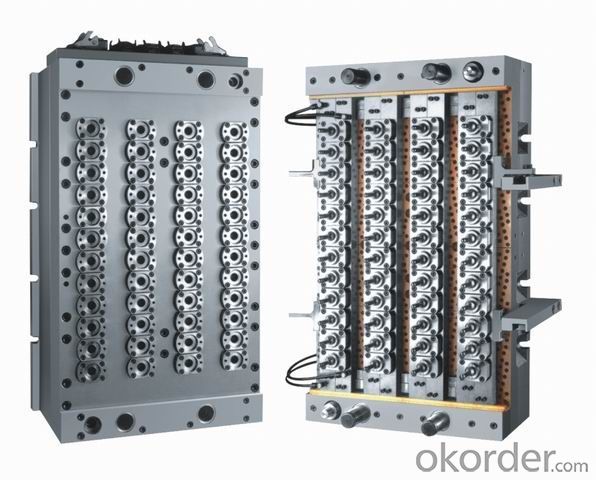

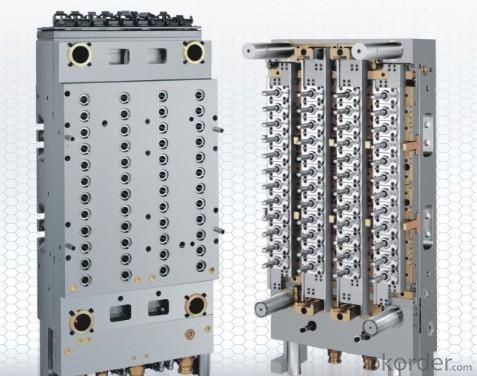

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

. Can supply with both Mold & Molded parts

. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.