Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:2000 m.t./month

Product Description:

Wooden pattern coated Aluminum coil /anodized aluminum coil 1100/3003 :

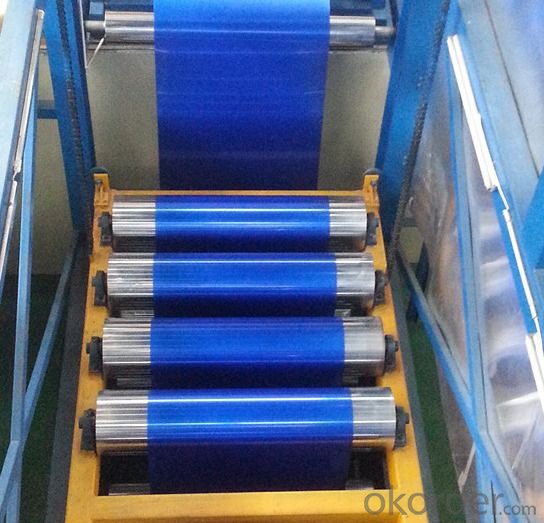

Our PVDF coated color aluminum coil is made of high-performance aluminum sheet and PVDF coating through advanced roller coating process.

Features:

1) Wear resistance 2) impact resistance 3) highly tensile strength 4) easy fabricating 5) UV resistance 6) weather resistance 7) corrosion- resistance 8) various colors

Aluminum foil range:

Thickness: 0.18mm-1.6mm

General Width: 1240mm, 1270mm, 1520mm, 1570mm, other special widths according to customer requirements;

Aluminum alloy: 1100,3003,8011,3105,5052, other alloys according to customer requirements.

Applications:

PVDF coated aluminum coil is a favorably choice of material for high-quality aluminum curtain wall, aluminum veneer sheet, Honeycomb panel. Its products are widely used in airports, convention centers, hotels and other high-end architectural curtain wall decoration

Aluminum Plates:

Aluminum coils / plates are widely used in building renovation (aluminum panels, honeycomb panels, aluminum veneer, tiles, ceiling, doors, windows, etc.), food packaging (such as bottle caps, lids). They can be used as cooling and temperature control material in electrical equipment.

| Aluminium series | Alloy | Temper | Thickness | Width | Pattern | Usage |

| 1000 series | 1050/1060/1070/1100 | H0-H112 | 0.3mm-5.0mm | 300mm-2200mm | Sheet/Coil | Chemical equipment, food industry equipment |

2000 series | 2014/2017/2024 | O,T3,T4 | 100mm-1250mm | Sheet/Coil | General Mechanical Components | |

| 3000 series | 3003/3004/3005/3105 | O/H32/H34/H36/H38/H116 | 0.2mm-6mm | 400mm-2000mm | Sheet/Coil | Building, PP cap material |

| 5000 series | 5005/5052/5083/5086/5182/5754 | O/H32/H34/H36/H38/H116 | 0.12mm-10mm | 20mm-2000mm | Sheet/Coil | Architectural decorative pieces, conductor, cookware |

| 6000 series | 6061/6205/6009/6010 | O/T4/T6 | 0.6mm-5mm | 100mm-1800mm | Sheet/Coil | Industrial structures, ships, trams, furniture components |

| 7000 series | 7038/7050/7075 | O/T6/T76 | 0.1mm-3.0mm | 400mm-2000mm | Sheet/Coil | Refrigerated containers, cryogenic equipment and storage tanks |

Quality Standard:

| Test Item | PE | PVDF | ||||||

| Chromatism(ΔE) | Ceiling Decoration | Engineer Ceiling | Primer Print | Back Print | Ceiling Decoration | Engineer Ceiling | ||

| ≤0.5 | ≤0.7 | ≤0.8 | ≤2.0 | ≤0.5 | ≤0.7 | |||

| Pencil Hardness | ≥HB (No Crack or peel off) | |||||||

| Adhensive Resistance | Grade 0;No crack or peel off after the circling&pasting | Grade 0;No crack or peel off after the circling&pasting | ||||||

| Impact Resistance | ≥0.5mm | 0.3-0.5mm | ≥0.5mm | 0.3-0.5mm | ||||

| 50kgs.cm | 20kgs.cm | 50kgs.cm | 20kgs.cm | |||||

| Boiling Water Resistance | no changes by circling after 2h boiling | no changes by circling after 2h boiling | ||||||

| T-Bend Flexibility | composite panel | Ceiling Decoration | Engineer Ceiling | Primer/Back Print | Composite Panel | Ceiling Curtain | ||

| ≤2T | ≤1T | ≤2T | ≤3T | ≤2T | ≤2T | |||

| Coating Thickness(μm) | Topcoat | Primer coating | Double printing | Back Print | Topcoat | Back Print | total coating thickness | |

| ≥16 | 9~11 | 25~28 | 9~12 | 18-20 | 9~11 | 25-28 | ||

| Solvent Resistent | Single print≥100 times | Double print≥200 times | Back Print:30-70 times | Back Print:30-70 times | ≥200 times | |||

FAQ of PE/PVDF Red Color Wooden Grains Aluminum Coil For Aluminum Composite Panel:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.