Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

Profile

The PE Model Jaw Crusher is the most widely used crusher in the field of mine and rock breakage at present. It has many advantages, such as large crushing ratio, uniformity strength of product, simple structure, convenient maintenance and so on. The PE Model Jaw Crusher is divided into two kinds of coarse breaking and fine breaking. The material can be processed with different fineness. The maximum compressive strength of the broken material is up to 250Mpa.

The PE Model Jaw Crusher is double-taggle jaw crusher which is widely used for rough-crushing or middle-crushing all kinds of ore and rock whose grain size is not more than 425mm and compressive strength is not more than 250Mpa in mineral、smelting、construction、highway、railway、water conservancy as well as chemical industries and other industries.

Features

- Optimized deep cavity crushing, and the ratio of feed and breakage is greatly improved

- Greater forging billet processing heavy eccentricity axle, stronger bearing capacity

- High quality hadfield’s manganese steel jaw plate and high quality cast steel movement jaw assembly makes the stability higher.

- The unique design of the centralized lubrication system, the component lubrication is faster, the maintenance work is low

- Digital analysis of the operation of each component, the internal structure is precise, and the service life of the equipment is greatly extended.

- Unique crusher chamber design, make wear-resistant parts use longer time, more crushing ratio, single machine energy saving 15%-30%

- Gasket type arrangement adjustment device, the material adjustment range is large, the flexibility is enhanced, it can meet the customer's various processing needs.

Technical Parameters

Type | Way-in Size (mm) | Max. Feed Size (mm) | Delivery Size (mm) | Processing Capacity (t/h) | Power (kw) | Dimension (mm) |

PE250*400 | 250*400 | 200 | 20-50 | 5-20 | 15 | 1430*1310*1340 |

PE400*600 | 400*600 | 350 | 40-100 | 15-60 | 30-37 | 1700*1732*1653 |

PE500*750 | 500*750 | 425 | 50-100 | 40-110 | 45-55 | 2035*1921*2000 |

PE600*900 | 600*900 | 480 | 70-160 | 90-180 | 55-75 | 2238*2203*2375 |

PE750*1060 | 750*1060 | 630 | 80-140 | 110-320 | 90-110 | 2722*2478*2692 |

PE900*1200 | 900*1200 | 750 | 95-165 | 220-450 | 110-132 | 3800*3166*3045 |

PE1000*1200 | 1000*1200 | 850 | 200-300 | 280-560 | 110-160 | 5350*4280*3050 |

PE1200*1500 | 1200*1500 | 1000 | 150-350 | 300-800 | 160-220 | 4590*3342*3553 |

PEX150*250 | 150*250 | 120 | 10-40 | 1-3 | 5.5 | 896*745*935 |

PEX150*750 | 150*750 | 120 | 18-48 | 5-16 | 15 | 1200*1500*1200 |

PEX250*750 | 250*750 | 210 | 25-60 | 15-30 | 22-30 | 1667*1545*1020 |

PEX250*1000 | 250*1000 | 210 | 25-60 | 15-50 | 30-37 | 1550*1964*1380 |

PEX250*1200 | 250*1200 | 210 | 25-60 | 20-60 | 37-45 | 3045*1745*1450 |

PEX300*1300 | 300*1300 | 250 | 20-90 | 20-85 | 55-75 | 2000*2320*1730 |

PEX500*2150 | 500*2150 | 425 | 50-150 | 80-300 | 110 | 3380*3867*2870 |

Structure & Working Principle

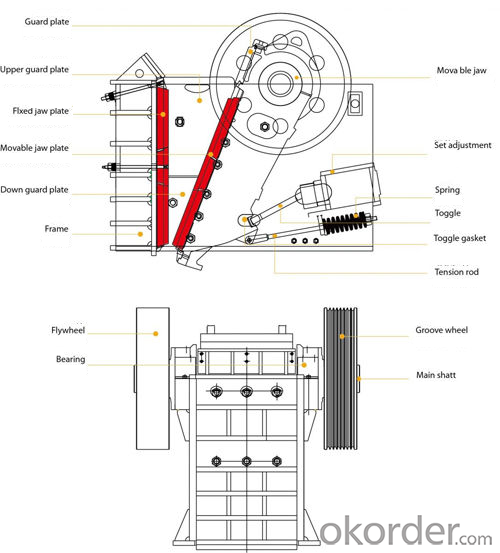

The crusher is mainly made up of the following parts:

1. Frame components; 2. Fixed—jaw plates; 3. Upper protection plate; 4.Down protection plate;5. Moving jaw components; 6.Adjustment components; 7.Pull rod components. 8. Rail components. 9.Lubricartion components; 10.Fundamental components.

The crusher is motor powered. By motor pulley, triangle belt and geneva wheel drive the eccentric shaft and make the moving jaw move along a scheduled track back and forth. Then the material in the crusher chamber (which is made up of fixed—jaw plate, moving jaw plate and edge plate) is crushed and the finished product is discharged through the below discharge opening.

-Frame components

The frame of the jaw crusher must be of enough intension and stiffness, because it suffers from the impulsive load when working. The frame is weldment. The front wall of the frame is equipped with fixed jaw plate, and the left and right inside wall is equipped with upper edge plate and lower edge plate. The moving jaw plate and fixed jaw plate is of high manganese steel castings. In order to prolong its service life, the upper and lower shape is designed symmetry, so when one end is worn, the other end can be used.

-Moving jaw component

The moving jaw is of high quality casting structure; its inner bore and groove have been through accurate processing and inspection to guarantee safety and reliability. Eccentric shaft is of high quality and high strength forged steel. It has been through several precision machining, heat treatment and flaw detection examination, so it’s of enough intension and stiffness. The bearing adopts four suits self-aligning roller bearing, and it’s of good bearing and self aligning performance. Flywheel and geneva wheel are of high quality iron casting and its weight and structure can guarantee the balanced work of the crusher. The position on the eccentric shaft of flywheel and geneva wheel can be exchanged.

-Elbow plate and adjusting components

Elbow plate is casting through accurate calculation. It is not only the driving components, but also the breaking piece of crusher. When the material that cannot be crushed in crusher, it may cause the crusher overload than usual, then elbow plate will be broken to protect the equipment from damage. Elbow plate and elbow plate mat adopt rolling contact, there is little friction under normal use, and it only needs to coat one layer of lubrication grease on the contact surface. Adjusting component is used to adjust the discharging opening size, and adjust the wear between compensation jaw plate, elbow plate and elbow plate mat.

-Rail component

Track is fixed on the basis of reinforced concrete through the anchor bolts. Motor is installed on the track; the frame is embedded in the groove of railway. Adjust the distance between motor and main machine according to the tightness of triangle belt. When the distance is decided, use the adjusting bolt to fix the base of motor, in case the motor shift.

-Lubrication components

Use oil gun to fill oil in oil cup. This way of filling oil is direct and has little failure.

Security and Operating Regulations

- Operators can only operate the machinery after studying security and technique.

- During the running of the crusher, it is strictly prohibited to do any adjustment, cleaning or inspecting.

- It is prohibited to look into the crusher from its upper part during the operation.

- It is prohibited to carry materials from the crusher chamber behind feed inlet by hand.

- Electric device should be ground connection. Electric wire should be insulation and laying in the steel tube.