Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

PC Lamp Light LED Tube Profile Making Machine Extrusion Production Line

Our company in PC lamp extrusion production line with many years of experience, has been general customers approval.

This production line is mainly used to produce PC fluorescent tubes, LED lamp (LED fluorescent tubes), PC tube, transparent double-color tube, grind arenaceous pipe and fluorescent lamp categories include smooth, double-color, grinding, sandblasting, light diffusion, semicircle, etc.

PC tubes chimney as long as used to manufacture LED energy-saving lamps, LED energy-saving lamps due to its privileged energy-saving effect, more and more get the market approbate, such as the ordinary sunlight 40 w light intensity, LED lamp only need 12w can achieve the same intensity, Moreover LED fluorescent lamp of long service life, and does not have mercury pollution.

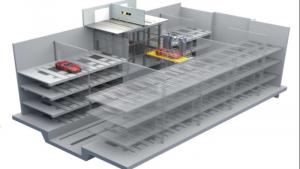

Pc tube extrusion production line is mainly composed of chimney profiles extrusion host, 3d electric calibrating bench, belt gauzing machine, cutting machine, feeder components. Extrusion host adopt efficient extrusion screw, variable-frequency regulating speed technology, on the basis of various specifications of product configuration of different specification host, Calibrating bench adopt stainless steel wet pan, match domestic brands vacuum pump. Drawer adopts Siemens motor, frequency conversion control, manual or automatic electric lift, belt traction, Cutting machine adopts imported sawblade positioning cut off.

The whole production line includes the following parts:

1. Drying machine

2. SJ-45 single screw extruder

4. profile molds (make according to your requirements)

5. Vacuum cooling shaping table

6. Belt type tractor

8. Precise Cutting machine

9. Automatic Stacker

Advantage and application:

1. Automatic cutting machine, cutting process with synchronized traction,Cutting length of by laser positioning, automatic/manual/timer/counter/reminder,.Online cutting length error in (0.20mm)

2. The Extruder has frequency converter to save energy power/ Electricity

PC Profiles production line

Raw material granulator → Drying Machine → Extruder→ Vacuum Cooling Shape Table → Belt type double motor Drawing machine →Film device →Cutting Machine → Stacking Rack(final products)

The main technical parameters | |||||

Model | SJ-45 | SJ-55 | SJ-65 | SJ-80 | SJ-90 |

Screw diameter(mm) | φ45 | φ55 | φ65 | φ80 | φ90 |

Center Hight(mm) | 1000 | 1000 | 1000 | 1000 | 1000 |

Production capacity (kg/h) | 45 | 70 | 100 | 150 | 180 |

Screw Rotational Speed(r/min) | 90 | 90 | 90 | 90 | 90 |

Main Power(kw/h) | 11 | 15 | 22 | 30 | 45 |

Heater ouan | 2+2 | 3+2 | 4+3 | 4+3 | 4+4 |

Total installed capacity(kw) | 18 | 25 | 38 | 50 | 70 |

Weight(t) | 1 | 1.2 | 1.5 | 1.8 | 2.2 |