Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:10000 unit/month

Introduction

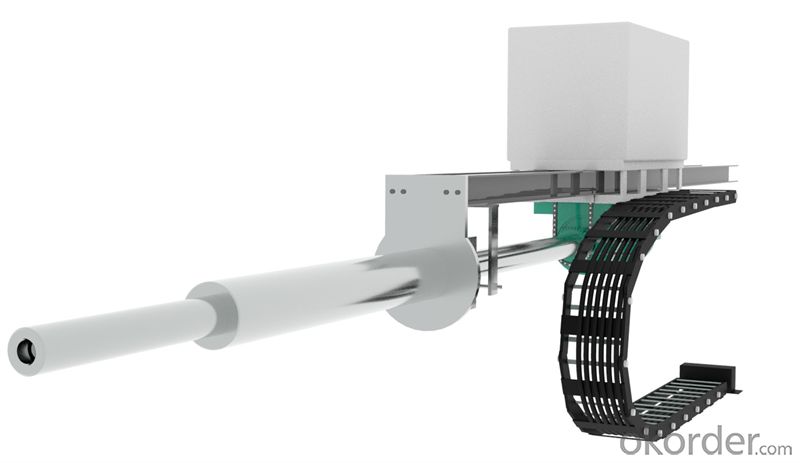

On line monitoring system for high temperature gas at kiln tail is specially designed for the pain point of the traditional analyzer sampling device. The system is mainly used to monitor the gas components in the smoke chamber at the end of the kiln in the dry cement production line.The system is mainly composed of sampling pretreatment system, circulating cooling system, electrical control system and gas analysis system.The sampling pretreatment system adopts automatic blockage removal, circulating cooling, rotating material shaking, three-stage back blowing and multistage purification to realize the stability and continuity of high temperature and high dust flue gas extraction.The gas analysis system adopts non-dispersed infrared technology to monitor NOX, CO, O2 and other gas concentrations in flue gas in real time.Kiln operators can reasonably adjust the ratio of air, coal and material according to the gas concentration information of each component, so as to achieve the goal of high quality, high efficiency and low energy consumption in cement production.

Characteristics

1. The high torque pneumatic transmission device ensures that the transmission does not jam and jump.

2. Multi - stage movable section slag cleaning rod ensures smooth and stable slag cleaning action.

3. The high-strength probe rod cleaning device removes the crust regularly to ensure that the probe rod is not coking.

4. High torque rotary shaking mechanism greatly improves the thermal deformation resistance of the probe rod

5. Automatic blockage removal design ensures sampling continuity

6. Automatic protection circuit improve the stability and reliability of the product under the interference of external factors.

7. The automatic data retention function reduces the data jitter under the backblow action and improves the data smoothness

8. The automatic safety warning device sends out high decibel sound and light alarm before the probe rod moves to improve the safety of the equipment.

9. Integrated cylinder block cleaning rod design and two flexible seal to ensure that the slag cleaning rod long-term action without leakage.

10. The use of back blowing front and large flow diaphragm pump can reduce the gas displacement time after back blowing and ensure the effective data proportion.

11. Circulation large area air cooling fan heat mechanism, improve the medium heat exchange capacity. Automatic temperature control circuit and intermittent fan start and stop energy saving and consumption reduction.

12. High temperature alloy and internal rod circulation cooling system are adopted to ensure the long-term stability of the equipment in the harsh environment such as corrosion and high temperature.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"