Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Profile

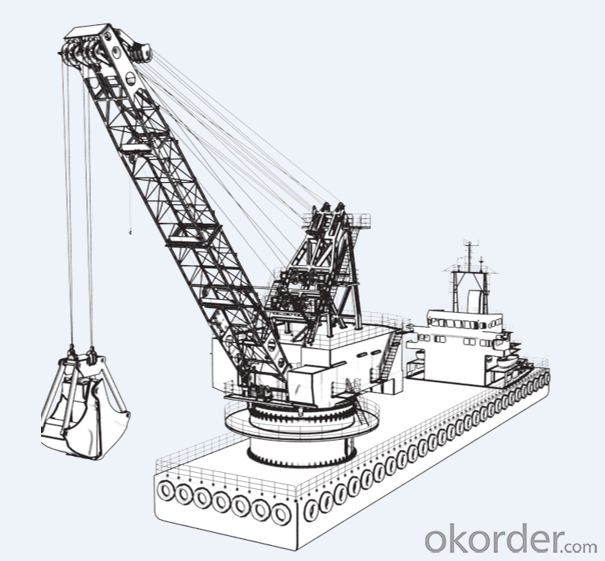

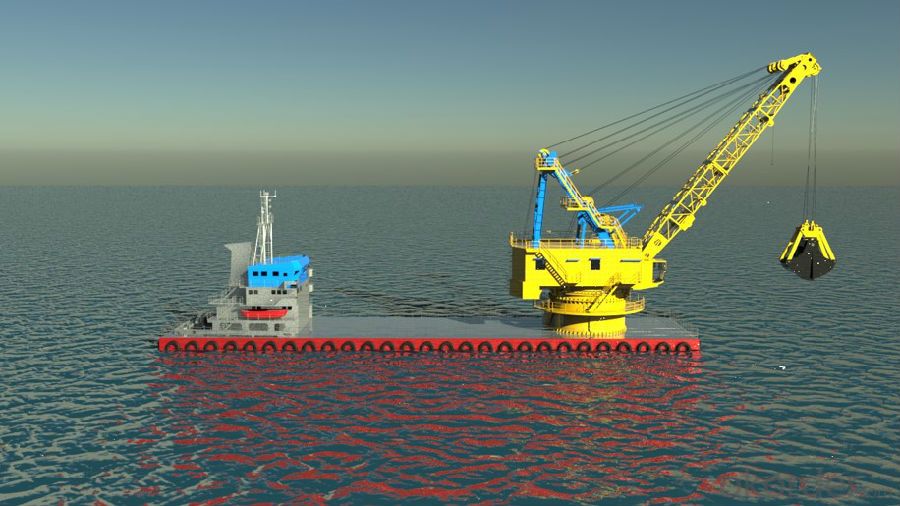

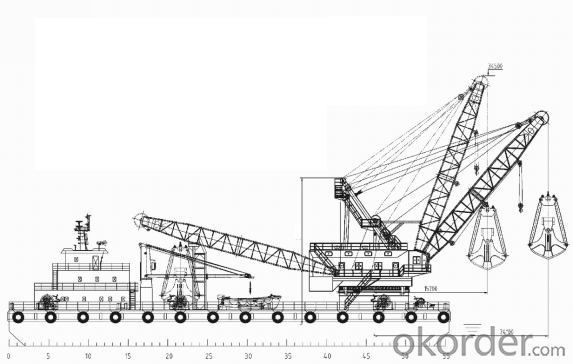

As a kind of working ship, the grapple dredge is mounted on the intelligent grab dredger. The intelligent grab dredger has following dual function, such as dredging operation and lifting the material by hook. The intelligent grab dredger is mainly used in channel dredging, harbor construction, salvage and rescue and other underwater operation. Also, it can be used in handling the material among the ships and bridge construction installing engineering of cross beam over water. By dint of changing the length of the steel cable, it can satisfy the requirement of various digging depth. The max digging depth can reach 70 meter. The intelligent grab dredger can be equipped with crampon and gravel heavy punch. Also the intelligent grab dredger can be considered as crane ship or boat rock cutter for preprocessed, which is thought as multipurpose working ship.

Characteristic

High performance cost ratio

The intelligent grab dredger breaks the monopoly and technical patent barriers of large dredging equipment market, which is monopolized by janpanese SKK, AI and other companies for a long period. The developed new type intelligent dredging equipment that adopts diesel engine-AC variable frequency drive can effectively reduce the purchasing cost and maintaining and using cost for latter period with domestic manufactured parts and auxiliary equipment.

The ship body of the dredger is imported and it is manufactured by domestic manufacturer. And, the dredge is manufactured by foreign countries. The body of the ship needs to be transported foreign country. Then, the dredge can be mounted on the body of the ship. Finally, it can be dragged into domestic to use. The overall new type intelligent dredger is manufactured in domestic, which can quite reduce the cost of the transportation and installation.

Intelligent control

The core of the intelligent grab dredger adopts Siemens S7-300PLC. The ProfiBus-DP system and frequency converter adopts communication junction, which can realize the protection of controlling and fault detect. By means of the predesign and intelligent control model, it can realize the fix dig deep, flat dredging by automatic controlling underwater. The accuracy of the flat dredging is 625px, which is more accurate than imported production(accuracy of flat dredging is 1250px).

Performance parameter

Ø Rated tension force of drum:70t

Ø Length of lazy arm:30m

Ø Working radius:15~23.5m

Ø Operation angle of lazy arm:71°~51°

Ø Applied grab:18m³×45t(dead weight)

Ø Hoisting speed of grab:0~60m/min

Ø Applied area:sheltered waters

Ø Steel cable grab:44ZAB-6×36WS+IWR-1770

Ø Rotating speed:1.2r/min

Ø Time of amplitude of variable of lazy arm:60s

Ø Steel cable of amplitude of variable of lazy arm:34-ZAB6×36WS+IWR-1770

Ø Max.lift:10m(above the water)

Ø The max.depth of dredge:50m(Vertical distance under the water)

Ø Applied temperature:-10~40°

Visualized simulation system

The electrical control system and construction positioning system contains sensing elements, which can realize the collecting data and input the collected data in the visualized simulation system. Together with the data communication technology, computer graphics, computer programming and sensor technology, it can realize visualization of grab underwater.

Convenient operation

It adopts PLC controlling, which has a high control accuracy. It is simple to realize the function that can reduce the numbers of the handling rods and pedal plates and the labor strength of the operator. The flat dredging and fix dig deep has two operation models, such as manual operation and automatic controlling. It has a accurate controlling(accuracy is 625px), which can avoid over dredging phenomenon. It adopts two hand shank and one pedal plate controlling with simple operation and high degree of automation.

Simple and direct maintenance

The overall intelligent grab dredger adopts AC variable frequency common DC bus multi-motor-drive controlling system with simple system and reliability.

The controlling system adopts ProfiBus-DP bus system. The fault of control loop is easy to check, which is convenient to maintain and examine and repair. All of the lifting mechanism and variable frequency mechanism adopt mature and reliable winch system. The rotating system adopts planetary gear system driven by electric motor with mature technology, reliability and convenient maintenance.

Low operation cost and low energy consumption

It adopts diesel generating set to provide power, which is to realize dynamic response. It makes the work of the diesel engine near the optimum efficiency curve, which can provide the fuel economy. It adopts twelve pulse rectification plan that can relieve the interference of the two harmonics and provide force and skill factor and transmission efficiency. It adopts generator sets+motor drive plan. And the overall efficiency can reach 75% which is 5% more than the same kind of equipment of Japan.

High-efficiency

Independent researched and developed intelligent controlling system can realize fix dig deep, flat dredging by automatic controlling, which gives full play to the ability of digging and reduces the time consuming caused by waiting operation and enhances productivity and reduces the manipulation strength. The intelligent grab dredging adopts mature high-power AC variable frequency drive and control technology. The performance of the AC variable frequency is reliable, which can avoid the stop caused by equipment fault and then influence the construction progress. Dual inverter are connected in parallel. And, it is inputted in one electrical machinery. It can make full use of overload capacity. It can realize triple digging overload capacity.