Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:1 unit/month

Municipal waste automatic sorting system

Municipal waste sorting can be from the source to eliminate landfill and incineration of environmental pollution problems, saving a lot of land resources, can produce huge social benefits, environmental benefits and economic benefits. Municipal solid waste automatic sorting system is suitable for a variety of domestic waste treatment process program, such as sanitary garbage landfill and treatment process, transfer station pretreatment process, incineration pretreatment process, composting treatment process and so on.

Product overview of municipal waste automatic sorting machine:

Municipal waste automatic sorting machine using advanced physical sorting technology, according to the characteristics of waste materials for sorting, can sort out a variety of garbage materials with high cleanliness, less impurity. Sorted garbage is fully utilized, reduce garbage turnover, solve the problem of garbage sorting.

Municipal waste automatic sorting machine can be sorted out of a muck, solid, waste plastics, residual organic matter, iron products five categories.

Advantages of municipal waste automatic sorting machine:

1. Equipment to achieve break bags and sorting at the same time.

2. Equipment covers an area of small, low energy consumption, operating costs less.

3. Installation is simple, all mechanical sorting, fully closed, do not cause secondary pollution.

4. Sorting accuracy is high, the separation of the material is relatively complete and clean.

5. Equipment can be moved, applicable to all kinds of living garbage centralized production sites.

Application of municipal waste automatic sorting system:

1. Used in domestic garbage transfer station, can reduce the amount of waste transport, reduce transportation costs, improve the utilization of renewable resources.

2. Used in domestic waste landfill, can reduce the amount of landfill, improve the service life of landfill.

3. Used in domestic waste incineration plant, can reduce the amount of harmful waste incineration.

4. According to different sites of domestic waste generation, can produce 30-500T capacity of the equipment.

Follow-up processing:

1.Waste plastics: can be sorted out of waste plastic bags for granulation and oil refining, etc.

2. Solids: beverage bottles, wine bottles, waste batteries and other recyclable.

3. Muck: muck can be fermented and composted.

4. Residual organic matter: after the crushing of vegetable leaves and food residues, fermentation and composting can be carried out.

5. Iron products: beer caps and other iron products can be recycled.

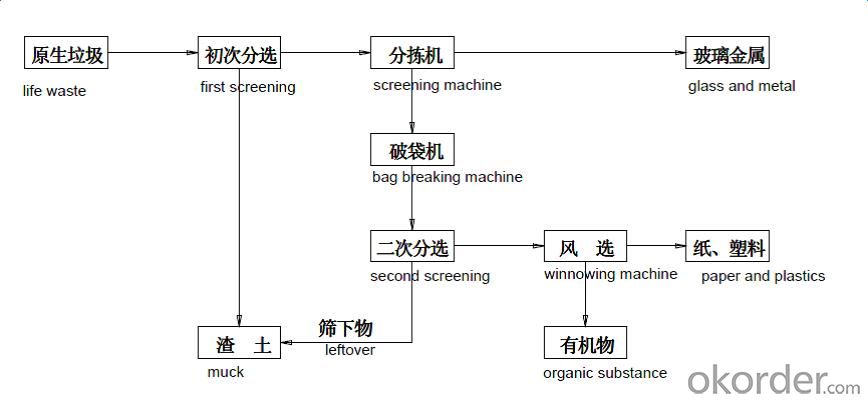

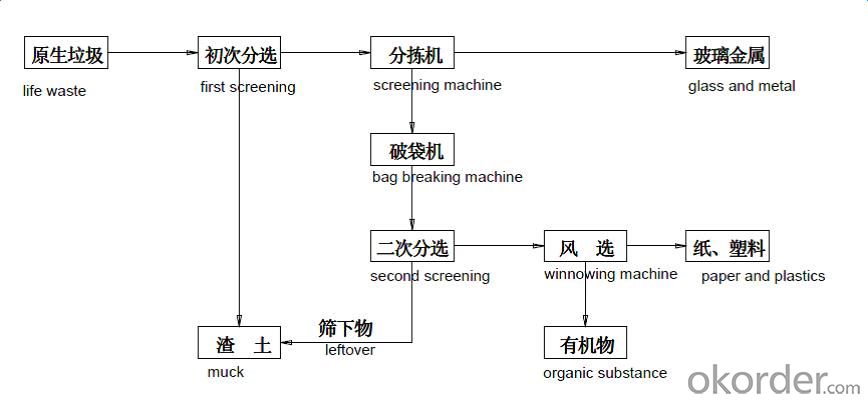

Processing chart:

Model | WMSC-30 | WMSC-60 | WMSC-100 | WMSC-300 | WMSC-500 |

Outline dimension(m) | 10*2.3*2.5 | 12*2.5*2.8 | 12*3*3 | 15*4*4 | 18*5*5 |

Voltage(v) | 380 | 380 | 380 | 380 | 380 |

Power(KW) | 22 | 40 | 64 | 100 | 150 |

Processing capacity(t/d) | 30 | 60 | 100 | 300 | 500 |

Classification rate | >85% | >85% | >85% | >85% | >85% |

Noise(db) | ≤54.4 | ≤54.4 | ≤54.4 | ≤54.4 | ≤54.4 |

Municipal waste automatic sorting system supporting equipment:

1.Municipal waste treatment dump truck:

a. Cabins can be dumped sanitation garbage truck with good seal performance: to ensure that the garbage truck in the transport process will not cause dust or leakage, prevent secondary pollution.

b. Good safety performance: closed box cover does not exceed the car body, does not affect the normal driving.

2. Drum sieve: used for block materials classification and separating powdery substance.

3. Hydraulic balers: all kinds of metal scrap can be extruded into various shapes of qualified charging.

4. Crusher: for processing larger than 8 mm of material.

5. Bag breaking machine: all the garbage bags in the garbage can be broken.

6. Four column garbage compression station: With multi-layer filtration, oxygen sterilization, spray, dust, deodorant, washing as one of the pollution control system, reducing the secondary pollution.

7. Linear vibrating sieve: screening less than 5mm of small materials.

8.Feeder: For feeding the material uniformly or quantitatively from the storage hopper or other storage equipment to the receiving equipment.

9. Vibrating conveyor: the vibrator is used to vibrate the chute, so that the material in a certain direction of sliding or throwing the continuous conveyor equipment.