Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:1 set

Supply Capability:100 set/month

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, PVC & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

U.S.A step motor & driving system with high precision synchronization system to make sure fast cutting speed and high precision.Interactive three kinds of data( U disk ,PC ,internet)

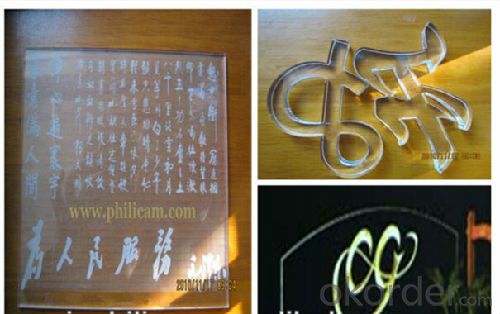

Software support multiple formats: AI, PLT, BMP, JPG, DXF, DST, seamless compatibility CorelDRAW, CAD, PHOTOSHOP, and other graphic software, easy operation. A LAN interface, two-way communication, to improve transmission speed and accuracy; allows a computer to control up to 254 laser equipment, greatly reduces the user cost of investment.

This kinds of model apply widely to fabric, leather, PU, wood, MDF, electronic parts, paper, acylicect.

2. Technical parameter:

Machine model NL-B2016

laser tube China-made CO2 glass laser tube

cooling way water cooling

laser power 80W/100W/130W/150W(optional)

cutting speed 0-800mm/s

engraving speed 0-1500mm/s

repeating precision ±0.05mm

Working area 2000x1600mm/3000x1600mm

power supply 1PH+1 AC 220V 15A 50/60HZ

machine measure

(LxWxH) 3000*2100*750mm 4000x3000x750mm

packing size

(LxWxH) 3150*2150*900mm 4150x3150x900mm

Weight Around N.W 1100kg G.W 1200kg

environment requirement Temperature 15℃-35℃,humidity 30%-80% noncondensing

3. Features of our Machine Line

1). After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically found glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the CNC cutting table. Under laser sensory element guidance, use laser-reader to get the position of the glass-sheet. Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2). After cutting, glass will move to the Breaking Glass Table. Start break bars and to break the glass. At this point, the whole process work is completed.

4. Main Introduction: Automatic glass loading machine

Product quality protection

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment.On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the covered amount of your payment.Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment.Product Details Company Profile Transactions History()

Report Suspicious Activity Company InformationPackaging & ShippingOur Services FAQ FAQ Quick Details Condition: New Machine Type: Insulating Glass Production Line Production Capacity: 1200piece/day

Place of Origin: Shandong, China (Mainland)Brand Name: PARKER Model Number: IGV22

Voltage: 220-380v 50hzPower(W): 23.7kwDimension(L*W*H): 21000x2100x3300mm

Weight: 4800kgsCertification: CE Warranty: 1 years

After-sales Service Provided: Engineers available to service machinery overseas Insulating glass type: flat ,LOW-E, Coated Glass Insulating glass: double/ 3 piece glazing press insulating glass

washing speed: 8-12m/min Max working speed: 50m/min Process insulating glass size: First min:250x480mm firstMax:2200x3000mm ,2th Max:2.2x4.8m,

processing thickness insulating glass: 12-60mmWashing 1 piece glass thickness: 3-12mmangle of inclination: 6°

Insulating glass production line: CNC Glass Cutting Machine Glass Edge polishing Machine: China Insulating Process line

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.