Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:10 m.t.

Supply Capability:1000 m.t./month

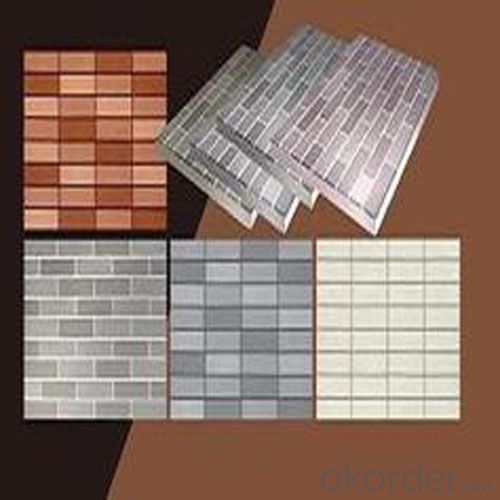

Products > REFRACTORY BRICKS

CNBM supply quality refractory bricks, which can be used in iron and steel,cement,glass,nonferrous metals,ceramic, petrochemical,etc.

Fireclay Bricks:Burned high-alumina 38% to 42% Magnesite Series Bricks:Burned magnesite,Burned fused magnesite-chrome,Direct-bonded magnesite-chrome, Magnesite-spinel,Magnesite-carbon and Alumina-magnesite-graphite SiC Series Bricks:Silicon nitride bonded SIC Silica Bricks:Silica bricks in glass,hot blast furnace,coke oven |

Products > REFRACTORY BRICKS

CNBM supply quality refractory bricks, which can be used in iron and steel,cement,glass,nonferrous metals,ceramic, petrochemical,etc.

Fireclay Bricks:Burned high-alumina 38% to 42% Magnesite Series Bricks:Burned magnesite,Burned fused magnesite-chrome,Direct-bonded magnesite-chrome, Magnesite-spinel,Magnesite-carbon and Alumina-magnesite-graphite SiC Series Bricks:Silicon nitride bonded SIC Silica Bricks:Silica bricks in glass,hot blast furnace,coke oven |

Physical and chemical index:

Item/Type | ZYM-23 | ZYM -26 | ZYM -28 | ZYM -30 | ZYM -32 | |

Classification temperature, Reference using temperature (oC) ≥ | 1260 | 1430 | 1540 | 1650 | 1760 | |

Bulk density (g/cm3) | 0.8 | 0.9 | 0.9 | 1.0 | 1.25 | |

Crushing strength (Mpa) ≥ | 1.3 | 1.6 | 2.1 | 16 | 16 | |

Modulus of rupture (Mpa) ≥ | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

Permanent linear change (oCX24h)% ≤ | 1350°C×4h | 1400°C×24h | 1510°C×24h | 1620°C×24h | 1730°C×24h | |

Thermal conductivity (W/m.k) ≤ | 800oC | 0.18 | 0.31 | 0.32 | 0.44 | 0.50 |

1000oC | 0.2 | 0.34 | 0.35 | 0.45 | 0.52 | |

1200oC | - | 0.40 | 0.41 | 0.47 | 0.56 | |

Chemical Analysis (%) | Al2O3 ≥ | 37 | 58 | 67 | 73 | 77 |

Fe2O3 ≤ | 1.0 | 0.8 | 0.8 | 0.6 | 0.4 | |

Application:

Light Weight Mullite Insulation Brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.