Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 m²

Supply Capability:1000 m²/month

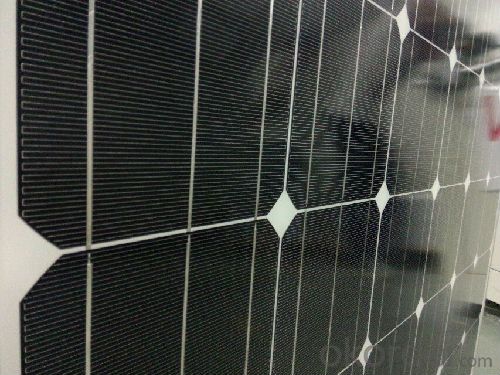

1.Solar panel energy system power from 165W-195W

2.100% TUV standard flash test

3.Certificate:TUV,UL,MCS

4.Quality Insurance

100% TUV standard flash test mono solar panel energy product system

1.What is 100% TUV standard flash test?

Flash test machine with TUV standard reference solar panel,all Propsolar Panel is tested with 100% TUV standard or standard higher than TUV standard

In the market,not all solar panel is real tested with TUV standard,Flash machine reference panel is not TUV standard,so the power is 2%-3% less than TUV standard.

2.Solar Panel Warranty

1)10 years limited manufacturing warranty

2)12 years for 90% of warranted minimum power

3)25 years for 80% of warranted minimum power

3.Solar Panel Electric Characteristics

CELL TYPE | 125 X 125 MONO SOLAR CELL | ||||||

ITEM | PS-M572165 | PS-M572170 | PS-M572175 | PS-M572180 | PS-M572185 | PS-M572190 | PS-M572195 |

Maximum Power(Wp) | 169.9 | 174.9 | 179.9 | 184.9 | 189.9 | 194.9 | 199.9 |

Open circuit Voltage (Voc) | 43.3 | 43.7 | 44.0 | 44.5 | 44.9 | 45.2 | 45.5 |

Short circuit Current (Isc) | 5.05 | 5.25 | 5.40 | 5.45 | 5.55 | 5.60 | 5.80 |

Maximum Power Voltage (Vm) | 35.3 | 35.5 | 35.6 | 36.0 | 36.3 | 36.5 | 36.7 |

Maximum Power Current (Im) | 4.67 | 4.79 | 4.92 | 5.00 | 5.10 | 5.21 | 5.31 |

Cell Efficiency [%] | 15.85 | 16.33 | 16.81 | 17.28 | 17.77 | 18.25 | 18.74 |

Module Efficiency [%] | 12.88 | 13.27 | 13.66 | 14.05 | 14.44 | 14.83 | 15.22 |

More Details:

Depending on construction, photovoltaic modules can produce electricity from a range of frequencies of light, but usually cannot cover the entire solar range (specifically, ultraviolet, infrared and low or diffused light). Hence, much of the incident sunlight energy is wasted by solar modules, and they can give far higher efficiencies if illuminated with monochromatic light. Therefore, another design concept is to split the light into different wavelength ranges and direct the beams onto different cells tuned to those ranges.[citation needed] This has been projected to be capable of raising efficiency by 50%. Scientists from Spectrolab, a subsidiary of Boeing, have reported development of multijunction solar cells with an efficiency of more than 40%, a new world record for solar photovoltaic cells.[3] The Spectrolab scientists also predict that concentrator solar cells could achieve efficiencies of more than 45% or even 50% in the future, with theoretical efficiencies being about 58% in cells with more than three junctions.

The life of the solar panels is determined by the Solar Energy Solar Cells, tempered glass, EVA, TPT and other materials, usually with better materials manufacturers panels made out of life can reach 25 years, but with the impact on the environment, solar cell board materials will change with time and aging. Normally used in 20 years of power will decay by 30%, it will be used in 25-year power attenuation of 70%.

Inspection and Maintenance of Solar Energy Solar Cells:

1. Check whether the damaged Solar Energy Solar Cells, to be promptly found and replaced.

2. Check the battery cables and the ground plate is good contact, without loss phenomenon.

3. Check the wiring at the combiner box if there is fever phenomenon.

4. Check the battery plate bracket loose and breakage.

5. Cleaning up around the panels shielding panels weeds.

6. Check whether the panel surface coverings.

7. Check the battery guano on the plate surface, and clean it if necessary.

8. The cleanliness of the panels were identified.

9. Windy weather to deal with solar panels and frame to conduct audits.

10. Snow days to respond in a timely manner to clean up the panel, the panel surface to avoid the frozen snow.

11. Heavy rain should check all waterproof seal is good, whether the water leakage.

12. Check if there are animals into the power station to the battery plate damage.

13. Hail response panel surface to conduct audits.

14. The battery plate temperature is detected, and the ambient temperature is compared for analysis.

15. Check it out on the issues to be addressed promptly analyzed and summarized.

16. To do detailed records of each inspection, in order to analyze later.

17. Summary records for analysis and archiving.