Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:10 pc

Supply Capability:1000000 pc/month

Monocrystal Solar Energy Cell

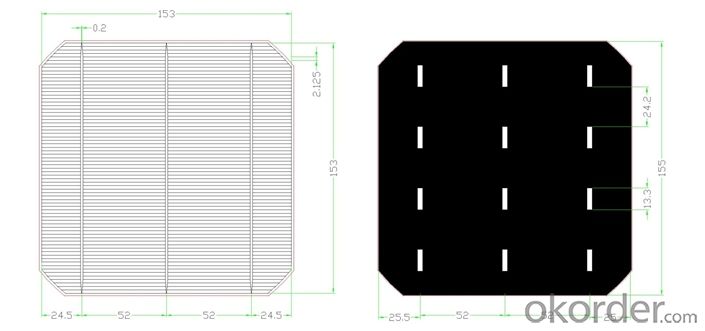

type:156M

appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

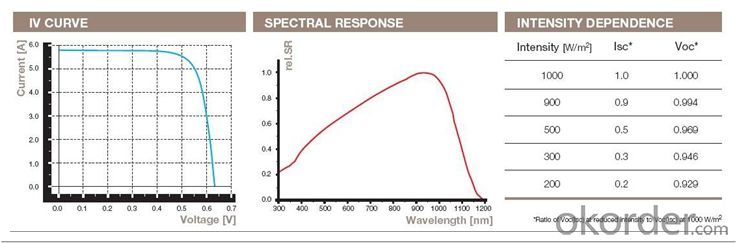

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

remark:our company cells as per working current concentrate principle,separate the first and the second grade

Factory Picture of Solar Cells

FAQ

We have organized several common questions for our clients,may help you sincerely:

What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

Can you do OEM for us?

Yes, we can.

How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

Brief introduction of Monocrystal Solar Energy Cell

Silicon rods, materials performance indicators in order to reduce production costs, and now terrestrial applications such as solar cells using solar grade somewhat relaxed. Some also use semiconductor device processing materials and discard the head and tail of silicon materials, solar cells drawn into complex dedicated silicon rods.

The silicon rods cut into pieces, usually 0.3 mm thick sheet. Processing solar cells, the first doping and diffusion in silicon, a trace amount of dopant is generally boron, phosphorus, and antimony. Diffusion is carried out in a quartz tube into a high-temperature diffusion furnace. Thus formed P> N junction on the wafer. Then using a screen printing method, fine with a good paste into a grid line printed on the wafer, after sintering, while forming the back electrode and the surface coated with antireflection gate line source to prevent a large number of photons it is reflected off the smooth surface of the wafer. Thus, the monomer Monocrystal solar energy cells are produced. After single-chip random testing can be assembled according to the required specifications into a solar cell module (solar panel) by the method of series and parallel to a certain output voltage and current.

Difference between Monocrystal Solar Energy Cell and polycrystalline silicon solar panels:

Polycrystalline silicon solar cells and Monocrystal solar energy cells is no different. Life and stability of polycrystalline silicon solar cells and Monocrystal solar energy cells are good. Although the average conversion efficiency of silicon solar cells is higher than the average conversion efficiency of polycrystalline silicon solar cells of about 1%, but because of Monocrystal solar energy cells can be made quasi-square (four to the top of the arc), when the composition of the solar cell module when there is a part of the area filled up, and polycrystalline silicon solar cells are square, there is no problem, so the efficiency of the solar cell module is the same.

In addition, because the manufacturing process two types of solar cell materials is not the same, polycrystalline silicon solar cell manufacturing process energy consumed than Monocrystal solar energy cells is about 30% less.