Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

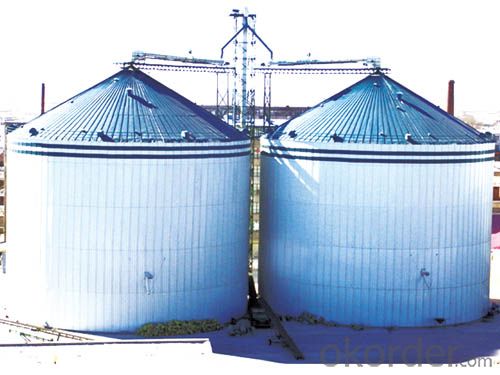

Mineral Powder Silo Cement Factory Equipment Cement Silo

Main Structure of Mineral Powder Silo

Voltage: 380V

Power(W): Cement Silo for Cement Factory

Dimension(L*W*H): As Per Size of Cement Silo for Cement Factory

Weight: As Per Size of Cement Silo for Cement Factory

Certification: ISO CE SGS

Warranty: 1 Year for the Cement Silo for Cement Factory

After-sales Service Provided: Engineers available to service machinery overseas

Safety: Double Direction Pressure Relieve Valve

Bottom Type: Hopper Type For Cement Silo for Cement Factory

Auxillary System-1: Vibrator

Auxillary System-2: Cement Block Breaker System

Auxillary System-3: Dedusting System

Auxillary System-4: Cement High/Low Level Indicator

Auxillary System-5: Cement Loading Pipe

Auxillary System-6: Cement Discharging Mouth

Type: Spiral Folding Lipp Cement Silo for Cement Factory

Customerized Design: Service Available

Main Features for Mineral Powder Coment Silo

| Please Click It to Get More Information → | Size Below 50ton Cement Silo | ||

| Processing Method | Spiral Folding | Bolt Assembly | Welding |

| Materials | Hot Galvanized Steel Can Use Special Materials Required | Carbon Steel Can Use Special Materials Required | Carbon Steel |

| Capacity | 200-7000ton/silo | 50-200ton/silo | Below 50 ton |

| Bottom Type | Flat or Hopper | Hopper | Hopper |

| Foundation Type | Concrete or Steel Structure | Concrete or Steel Structure | Concrete,Steel Structure |

| Application | Cement Storage | Cement Storage | Cement Storage |

| Features | 1) Spiral Folding Treatment Silo has the Max Sealing 2) Big Storage Volume 3) Short Poject Period, Sea Delivery Cost Saving 4) High Solidity 5) Refer Following Advantages for the Detail Features | 1) Bolt Asssembly,Fast Delivery Time, Easy Assemble &Move in Future 2) Medium Quantity Storage 3) Short Poject Period 4) High Solidity 5) Economical | 1) Cheap Cost 2) Small Size Storage 3) Fast Delivery 4) Easy Assembly and Move in Future |

| Optional Auxilliary Systems | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device 5) Explosive-Proof Double Direction Pressure Balance Valve | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device | 1) Dedust System 2) Level Indicator 3) Loading and Unloading System 4) Cement Block Break Device |

| TALK TO US, LET SRON WORK OUT YOUR INTEGRAL PLAN | ||

Spiral Folded Cement Silo for Cement Factory Advantages

1- With Max Assured Safety Consideration Leant from Our Over 3000 Units Silo Experience.

2- Spiral Folding, Max Sealing Performance, Can Have Fumigation System and Store Liquids

3- Connection Part is 5 Times the Thickness of Steel Plate, with Reinforcing Ribs and Wind Rings, Thus Assure Higher Strength and Solidity

4- Spiral Folding Silo is Integral Whole Body and with Longer Life Span to 25-40 Years

5- Fast Assembling and Easy Maintenance, the Project Time is Much Shorter than Bolt Assembly Silo

Application of Our Cement Silo for Cement Factory

1- Can store bulk cement for cement production factory

2- Can store cement used for concrete batching plant

3- Can store cement used for block productine line

4- Can store other mineral powders, coal slag, coal ash, gypsum, coal, special construction materials, rare earth metals etc.

5- Used in hydro-power industry

6- Other special area.

Picture: