Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:1000 set/month

1. Description

MHT light-duty slurry pump is designed for bentonite industry, abrasive and grinding tools manufacture, desulfation of power plant and conveyance of alumina ore slurry in aluminum plant, and is the ideal device matched with filter press and the optimal choice for conveying medium containing hard sundries. MHT is simple in maintenance, highly resistant against abrasion and corrosion, economical in operation and reliable in sealing. It is suitable for conveyance of bentonite, carbide slag, lime milk, coal ash, gypsum slurry and sand-bearing crude oil.

2. Application

Soda and inorganic salts: lime milk, carbide slag, salt mud.

Metallurgy: ore slurry for zinc, aluminium, copper, vanadium production.

Petrochemical industry: sand-bearing crude oil.

Paper-making industry: lime milk.

Fermentation industry: various fermenting liquid.

Environmental protection in power plant: coal ashm gypsum slurry.

3. Materials

For wetted parts in contact with medium, the common materials are as follows:

MCU, Cr15Mo13, DTM, M-3

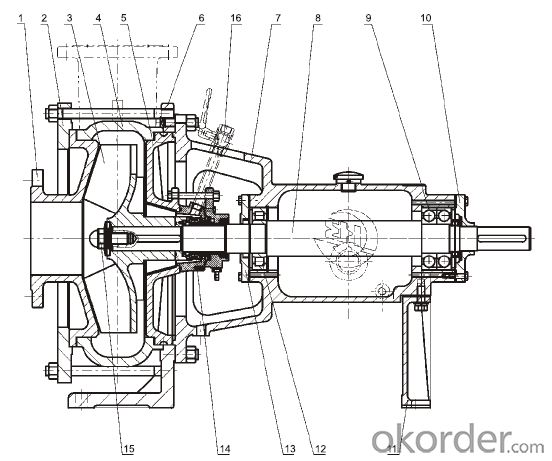

4. Pump Structure

5. Technical Data

Max working pressure 1.6MPa

Capacity: 2~1000m3/h

Head: 8~100m

Temperature: -20~180℃

6. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

5 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.