Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:350 m.t./month

Polyolefin:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Polyolefin:

1. Applications and cable specifications:

Type | Product | Application and cable specification |

HL112-1 | K1 class chemical cross-linkable low smoke halogen free high flame retardant EPDM rubber insulating compound for nuclear power cables | 1E grade K1 class chemical cross-linkable flame retardant EPDM rubber insulation of nuclear power cables |

HL113-1 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE rubber insulating compound for nuclear power cables | 1E grade K1 class chemical cross-linkable flame retardant rubber insulation of nuclear power cables |

HL113-7 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE filling compound for nuclear power cables | 1E grade K1 class chemical cross-linkable high flame retardant filling compound of nuclear power cables |

HL113-2 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE rubber jacket compound for nuclear power cables | 1E grade K1 class chemical cross-linkable high flame retardant rubber jacket of nuclear power cables |

HF112-1 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant EPDM rubber insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable flame retardant EPDM rubber insulation of nuclear power cables |

2. Description:

Low smoke halogen free flame retardant POE compound for nuclear power grade 1E class K1 cable, based on EPDM rubber and POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing:

The following temperature(°C) profile of extruder is recommended:

| Type | Processing Equipment | Compression ratio | L/D | Processing temp. °C | Recommended vulcanize temp. | |||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |||||

| HL112-1 | Common rubber extruder | 1.1:1~1.5:1 | 15:1~20:1 | 60-110 | 160-200 °C | |||||

| HL113-1 | ||||||||||

| HL113-7 | ||||||||||

| HL113-2 | ||||||||||

| HF112-1 | 50 | 90 | 110 | 115 | 120 | 120 | ||||

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties:

| Item | Unit | HL112-1 | HL113-1 | HL113-7 | HL113-2 | HF112-1 |

| Standard | Standard | Standard | Standard | Standard | ||

| Tensile Strength | ≥MPa | 8.5 | 8.5 | 6 | 9 | 8 |

| Elongation at Break | ≥ % | 200 | 200 | 70 | 150 | 200 |

| Thermal Aging | °C×d | 135×10 | 135×10 | — | 135×10 | 135×10 |

| Variation on TS/ EB | ≤ % | ±30/±30 | ±30/±30 | — | ±30/±30 | ±30/±30 |

| Thermal Prolongation 20N/cm2 | °C×min | 250×15 | 200×15 | — | 200×15 | 250×15 |

| Elongation Under Load | ≤ % | 175 | 175 | — | 175 | 175 |

| Permanent Deformation | ≤ % | 15 | 15 | — | 15 | 15 |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1015 | 1.0×1012 | — | 1.0×1012 | 1.0×1015 |

| Dielectric Strength | ≥KV/mm | 25 | 20 | — | 20 | 25 |

| Oxygen Index | ≥ % | — | 30 | 40 | 30 | — |

| Impact Brittleness Temperature | °C | -30 | -30 | -15 | -30 | -30 |

| Smoke Density Flaming | ≤ | 100 | 100 | 100 | 100 | 100 |

| Non Flaming | ≤ | 350 | 350 | 350 | 350 | 350 |

| Acidity of gases evolved (PH) | ≥ | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/cm | 10 | 10 | 10 | 10 | 10 |

| Toxicity Index | ≤ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water Absorption Test | °C×h | 85×336 | 85×336 | — | 85×336 | 85×336 |

| Variation on TS/ EB | ≤ % | ±40/±40 | ±40/±40 | — | ±40/±40 | ±40/±40 |

| 20°C Dielectric Constant (50HZ) | ≤ | 2.8 | — | — | — | 2.8 |

| Dielectric Loss Angular Tangent at 20°C (50HZ) | ≤ | 0.003 | — | — | — | 0.003 |

| Ozone Resistance | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Irradiation Test 3300KGy | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Thermal Life | ≥years | 60 | 60 | 60 | 60 | 60 |

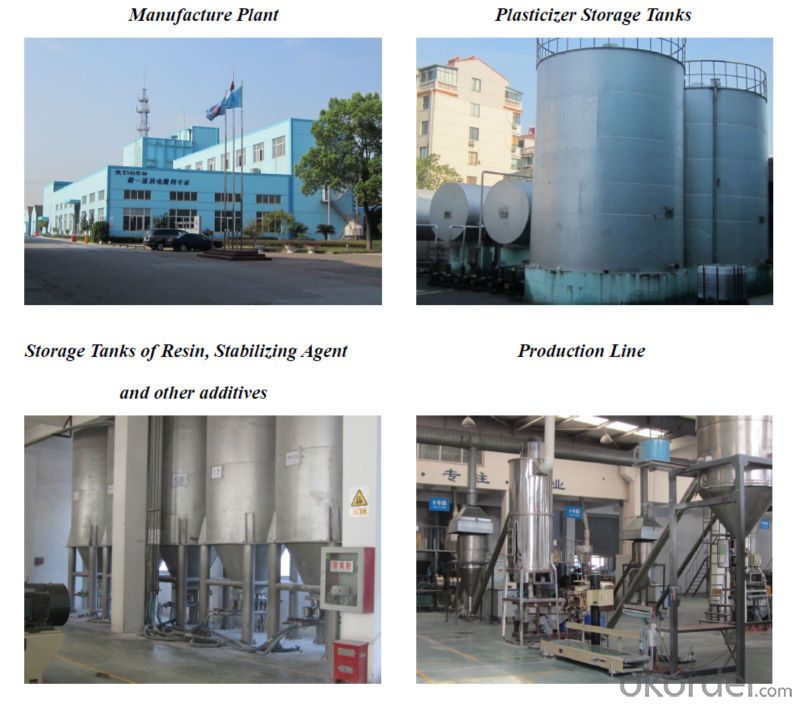

6. Company