Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:350 m.t./month

lszh compound:

1. Applications and cable specifications:

Type | Product | Application and Cable Specification |

FDW1186 | 110℃ Irradiation cross-linked, low-smoke, halogen-free and flame retardant POE jacket compound | 105℃ jacket for cross-linked flame retardant wires and cables, meeting the standard of HF-110-R, E-110-R of AS 3808. |

FDW1180 | 110℃ Irradiation cross-linked, low-smoke, halogen-free and flame retardant POE insulating compound | 110℃ Insulation for cross-linked flame retardant wires and cables, meeting the standard of R-E-110, X-HF-110, R-HF-110 of AS 3808. |

DW9022-C01 | 90℃ Thermoplastic Low-smoke, halogen-free and flame retardant POE jacket compound | 90℃ common jacket for flame retardant wires and cables, meeting the standard of HFS-90-TP and HFS-110-TP of AS 3808. |

2. Description:

High temperature resistant irradiation cross-linked low-smoke halogen-free and flame retardant POE compound, based on POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1:1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

Type | Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

FDW1186 | temperature °C | 90 | 125 | 140 | 145 | 145 | 145 |

FDW1180 | temperature °C | 90 | 125 | 140 | 145 | 145 | 145 |

DW9022-C01 | temperature °C | 125 | 145 | 150 | 160 | 160 | 160 |

Note:Compound should be dried at 60-70°C before use, which has been stored more than two months.

4. Irradiated dosage

The normal irradiated dosage(recommended) of high temperature resistant, irradiation cross-linked, low-smoke, halogen-free and flame retardant POE compound is 15 to 18 megarad.

5. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

6. Properties:

| Item | Unit | FDW1186 | FDW1180 | DW9022-C01 | |||

| Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | — | 1.48 | — | 1.23 | — | 1.34 |

| Hardness | Shore A | — | 86 | — | 81 | 94 | 92 |

| Tensile Strength | ≥ MPa | 6 | 12 | 5 | 9.5 | 6 | 11 |

| Elongation at Break | ≥ % | 125 | 160 | 125 | 400 | 125 | 360 |

| Thermal Aging | |||||||

| Aging Temperature | °C | 130±2 | 130±2 | 150±3 | 150±3 | 110±2 | 110±2 |

| Aging Time | h | 480 | 480 | 168 | 168 | 480 | 480 |

| Tensile Strength | ≥ % | 6 | 10 | Retention 70 | 85 | 6 | 8.7 |

| Elongation at Break | ≥ % | 100 | 150 | Retention 70 | 82 | 100 | 280 |

| Thermal Prolongation 20N/cm2 | °C×min | 200×15 | 200×15 | — | — | ||

| Elongation Under Load | ≤ % | 175 | 25 | 175 | 50 | — | — |

| Permanent Deformation | ≤ % | 15 | 0 | 15 | 0 | — | — |

| Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1011 | 2.0×1012 | 1.5×1012 | 3.0×1012 | 1.0×1011 | 2.0×1012 |

| Dielectric Strength | ≥KV/mm | 18 | 23 | 20 | 25 | — | — |

| Oxygen Index | ≥ % | 33 | 34 | — | 28 | 30 | 34 |

| Impact Brittleness Temperature | °C | — | — | — | — | — | — |

| Smoke Density Flaming | ≤ | 100 | 61 | — | — | — | — |

| Non flaming | ≤ | 200 | 142 | — | — | — | — |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.8 | 3.5 | 4.2 | 3.5 | 4 |

| Conductivity of gases evolved | ≤μs/cm | 2.5 | 0.9 | 100 | 6 | 100 | 28 |

| Oil Resistant Test | |||||||

| Test Temp. Time | °C×h | 120×18 | 120×18 | — | — | — | — |

| Retention on Tensile Strength | ≥ % | 60 | 65 | — | — | — | — |

| Retention on Elongation at Break | ≥ % | 60 | 72 | — | — | — | — |

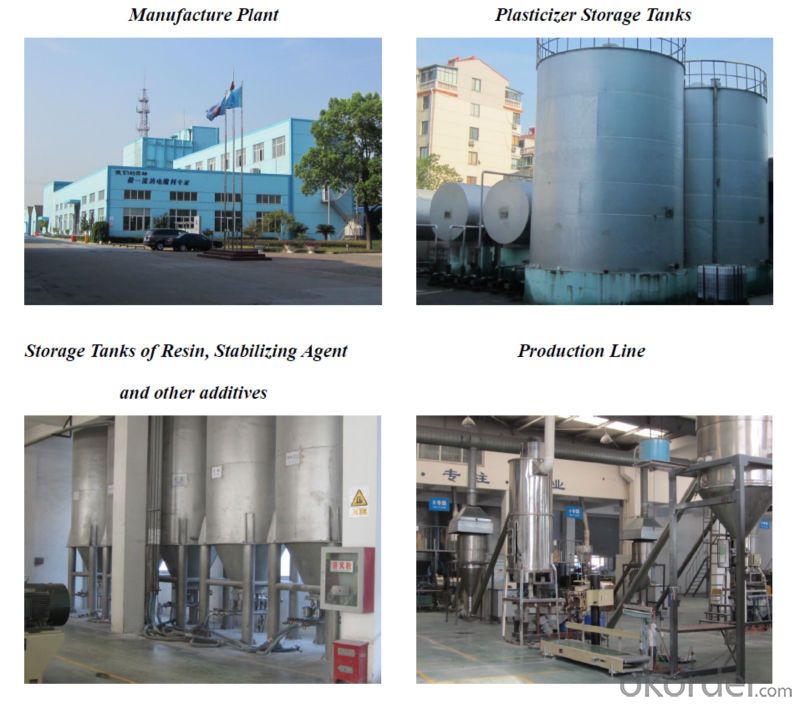

7. Company