Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:350 m.t./month

cross link compound:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Cross Link Compound:

1. Applications and cable specifications:

Used for 125°C less than 3KV locomotive cable, meeting GB/T 12528-2008. Suitable for environment with pollution of mineral oil and fuel oil.

2. Description:

Irradiation low smoke halogen free flame retardant POE compound for locomotive cable, based on special high oil resistant POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, assistant crosslinker and other special additives.

3. Processing:

The compound can be processed with conventional extruders, and the normal PVC screw with a minimum 20:1 L/D. It is better if use low compression ratio screw.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature °C | 130 | 145 | 150 | 150 | 145 | 145 |

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Irradiated dosage:

The normal irradiated dosage(recommended) of irradiation cross-linkable low smoke halogen free flame retardant POE compound is 13 megarad.

6. Properties:

| Item | Unit | JFDW6125-G01 | JFDW1125-J01 | JDW1150-J02 | FDW6125-A01 | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | 1.44 | 1.43 | 1.34 | 1.45 | |||||

| Hardness | Shore A | 91 | 98 | 98 | 97 | ||||

| Tensile Strength | ≥Mpa | 9 | 13.7 | 10 | 15.8 | 30 | 32.6 | 17.8 | |

| Elongation at Break | ≥% | 125 | 191 | 125 | 273 | 100 | 230 | 170 | |

| Thermal Aging | Condition °C×h | 158×168 | 158×168 | 178×168 | 158×168 | ||||

| Variation on tensile strength | ≤ % | -25 | -6 | -25 | -12 | Not break | Not break | -25 | -8 |

| Elongation at Break | ≥% | 100 | 174 | 100 | 231 | 100 | 162 | ||

| Variation on Elongation | ≤ % | -40 | -9 | -40 | -15 | -40 | -5 | ||

| Thermal Prolongation: 20N/cm2 | °C×min | 200×15 | 200×15 | 200×15 | |||||

| Elongation Under Load | ≤ % | 100 | 20 | 100 | 75 | 100 | 15 | ||

| Permanent Deformation | ≤ % | 25 | 0 | 25 | 0 | 25 | 0 | ||

| Ozone Resistance | |||||||||

| Ozone density and time, Method A | ppm×h | 250-300×24×25 | 250-300×24×25 | 250-300×3 | 250-300×24×25 | ||||

| Ozone density and time, Method B | ppnm×h | 200±50×72×40 | 200±50×72×40 | 200±50×72×40 | |||||

| Surface after test | Non cracking | pass | Non cracking | pass | No fissure and not break | Non cracking | pass | ||

| Oil resistance | Oil | 20# machine oil | 20# machine oil | 902# machine oil | |||||

| Condition °C×h | 100×70 | 120×70 | 100×70 | ||||||

| Variation on Tensile Strength | ≤ % | -50 | -22 | Variation of outer diameter ≤ ±5 | ±30 | -16 | |||

| Variation on Elongation | ≤ % | -50 | -35 | Not break | ±40 | -11 | |||

| Oil resistance | Oil | 0# diesel | 0# diesel | 903# diesel | |||||

| condition °C×h | 70×168 | 70×168 | 70×168 | ||||||

| Variation on Tensile Strength | ≤ % | -55 | -38 | Variation of outer diameter ≤ ±5 | ±30 | -18 | |||

| Variation on Elongation | ≤ % | -55 | -47 | Not break | ±40 | -26 | |||

| Impact Brittleness Temperature | ≤°C | -40 | pass | -40 | pass | -60 winding | pass | -40 | pass |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1012 | 4.8×1012 | 1.0×1012 | 2.0×1013 | 1.0×1012 | 2.0×1013 | ||

| Dielectric Strength | ≥MV/m | 20 | 27 | 20 | 27 | ||||

| 150°C high temperature stress | ≤ % | 50 | 13 | ||||||

| friction resistance (round trip) | ≥ times | 1000 | pass | ||||||

| Oxygen Index | ≥ | 30 | 33 | 30 | 34 | 30 | 34 | ||

| Smoke density Flaming | ≤ | 100 | 67 | 100 | 83 | 100 | 67 | 100 | 65 |

| Non Flaming | ≤ | 200 | 164 | 200 | 185 | 200 | 164 | 200 | 196 |

| Acidity of gases evolved (PH value) | ≥ | 4.3 | 5.1 | 4.3 | 5.0 | 4.3 | 5.1 | 4.3 | 5.0 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 2.0 | 10 | 2 | 10 | 2 | 10 | 2 |

| Toxicity Index | ≤ | 5 | 2 | 5 | 2 | ||||

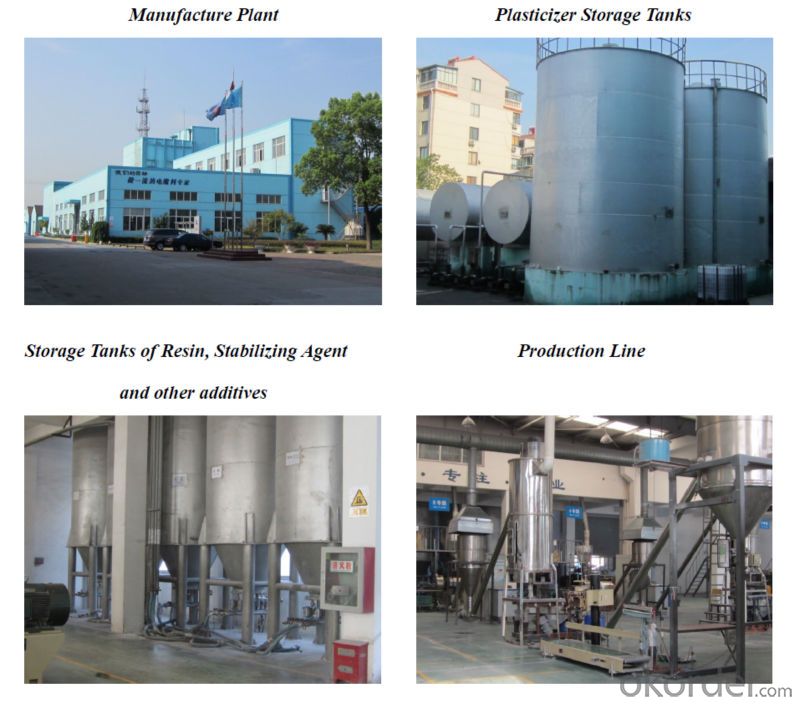

7. Company