Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:1000000 m.t./month

General Information of Ceramic Fiber Bulk

l CMAX ceramic fiber bulk is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process. Ceramic Fiber Bulk is the optimum material for the production of fiber textile and also the perfect material for sealing, filling and insulating in high-temperature environment.

l Ceramic fiber bulk are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃, 1100℃, 1200℃ and 1350℃.

Feature of Ceramic Fiber Bulk

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

Image of Ceramic Fiber Bulk

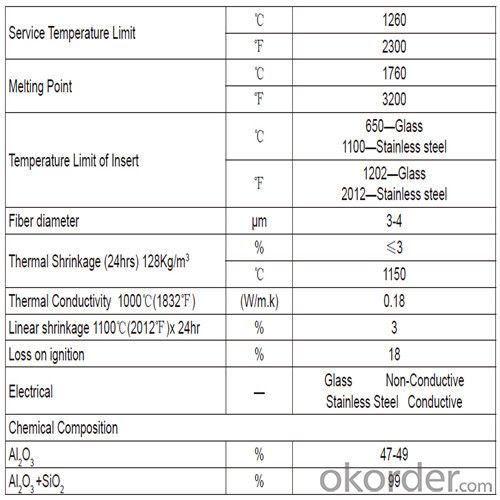

Technical Data of Ceramic Fiber Bulk

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

o-hansi-theme-font:minor-latin;mso-bidi-font-family: Arial;background:white;mso-font-kerning:0'>℃, 1100℃, 1200℃ and 1350℃.

Feature of Ceramic Fiber Bulk

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.