Loading Port:Ningbo

Payment Terms:TT or LC

Min Order Qty:1 unit

Supply Capability:720 unit/month

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG300-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 673-980g

Clamping Force: 3000 kn

Opening Stroke: 570 mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Plastic Rubber Injection Moulding Machine

Warranty: One Year

Material: Stainless Steel

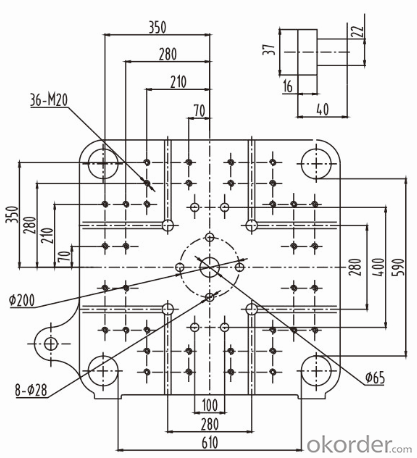

Space between Tie Bar: 610*590

Screw Diameter: 58-65-70 mm

Machine weight: 9.1T

Ejector stroke: 160mm

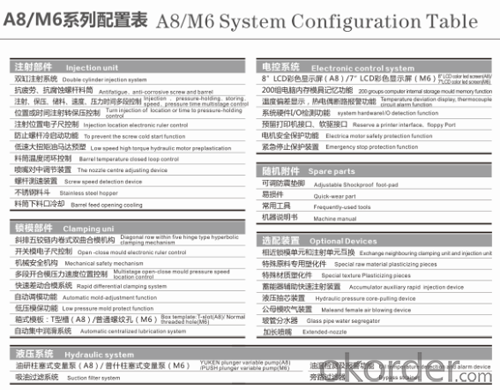

| Description | Unit | LOG-300A8 | ||

| international recognized models | 1400/300 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 740 | 929 | 1077 |

| Shot volume | g | 673 | 845 | 980 |

| Oz | 23.5 | 29.5 | 34.2 | |

| Screw diameter | mm | 58 | 65 | 70 |

| Injection diameter | mpa | 190 | 151 | 130 |

| Screw L:D ratio | 24:01:00 | 22:01 | 20:01 | |

| Scerw steoke | mm | 300 | ||

| Screw rotate speed | r/min | 0-150 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3000 | ||

| Opening stroke | mm | 570 | ||

| Platen size | mm*mm | 870*850 | ||

| Space between tie bars | mm*mm | 610*590 | ||

| Maldthickness | mm | 200-600 | ||

| Platen Mix stroke | mm | 1170 | ||

| Ejection stroke | mm | 160 | ||

| Ejcetion force | kN | 77 | ||

| Power/Elcetric Heating | ||||

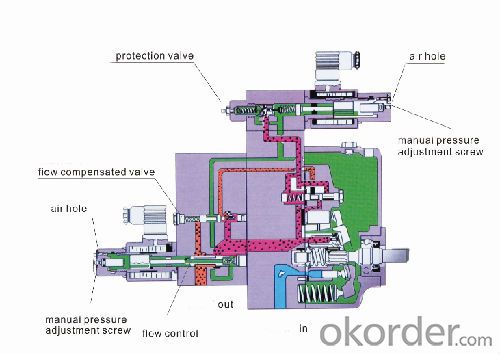

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 29 | ||

| Heating power | kw | 23.6 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5 | ||

| Tank volume | L | 380 | ||

| Machine dimesions | m*m*m | 6.4*1.6*2.18 | ||

| Weight of machine | kg | 11000 | ||

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

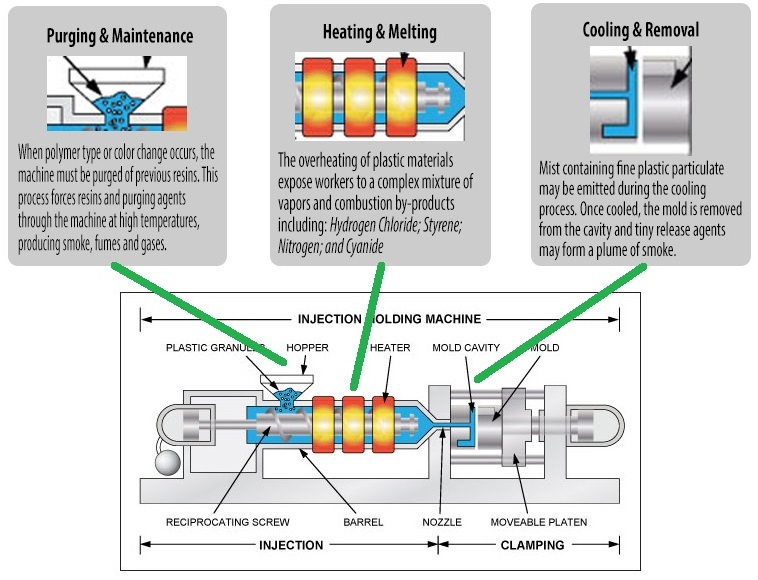

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN