Loading Port:China Main Port

Payment Terms:TT OR LC

Min Order Qty:-

Supply Capability:-

HRB400 - Definition

That is the new standard name for HRB400 steel, grade three steel as the old name, as a kind of hot rolled ribbed bar. In the construction industry, three screw steel is the old saying.

Hot rolled ribbed steel grades by HRB and number of yield points minimumcomposition. H, R, B respectively (Hot rolled), hot rolled ribbed steel bar(ribbed), (Bars) the three word's first letter English.

HRB400 - Classification

Hot rolled ribbed steel bar is divided into HRB335 (the old number is 20MnSi),HRB400 (the old No. 20MnSiV, 20MnSiNb, 20Mnti), HRB500 three brands.

Hot rolled bars of fine grains in the grades of hot rolled ribbed bar after Englishabbreviation "fine" English (Fine) the first letter. Such as: HRBF335, HRBF400,HRBF500.

A suitable grade higher requirements for seismic structures: add E in the existing brands after (for example: HRB400E, HRBF400E).

HRB400 - the main purposes

Widely used in houses, bridges, roads and other civil engineeringconstruction.

HRB400 - the main origin

Screw thread steel producers in China are mainly distributed in the north and Northeast China, North China regions such as Shougang, Tang Gang, Xuan Steel, bearing steel, Shanxi Zhongyang steel plant, Baoding Purui the steel,the northeast area such as resistant, Bei Tai, Fushun Steel, these two areas account for about 50% of the total output in the screw thread steel.

The difference between the screw thread steel and round steel bar is provided with longitudinal ribs and transverse ribs surface, usually with two longitudinalribs and transverse ribs along the length direction of the uniform distribution.Screw thread steel belongs to the small steel steel, mainly used in reinforced concrete building components of the skeleton. In use requires a certainmechanical strength, flexural property of welding technology and properties.Screw thread steel billet production raw material for the carbon structure steelsmelting processing sedation or low alloy structural steel, finished steel for the hot rolling, normalizing or hot-rolled state of delivery.

The bending properties of HRB400 - reverse

According to the requirements of the buyer, screw steel for bendingperformance of reverse test.

Reverse bending test bending test bending center diameter than a corresponding increase in rebar diameter. The first positive bending 45 degrees, 23 degrees backward bending, reverse bending 23 degrees after.The reverse bend test, screw steel bending parts shall not generate cracksurface.

HRB400 - surface quality

Screw thread steel surface shall not be permitted to have crack, scarring andfolding.

Screw thread steel surface allows the bumps, but shall not exceed thetransverse rib height, depth of thread other defects on the surface of steel andheight shall not allow the deviation is greater than the location dimension.

HRB400 - dimension, shape, weight and permissible deviations

1 nominal diameter range and recommended diameter

Screw thread steel of nominal diameter range of 6 ~ 25mm, screw steelnominal diameter standard recommended for 6, 8, 10, 12, 16, 20, 25, 32, 40,50mm.

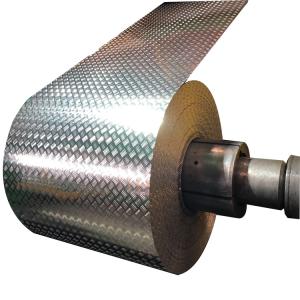

2 surface shape and size of the allowable deviation of rib steel plate

Ribbed Rebar shall meet the following basic rules of transverse ribs:

The included angle beta transverse rib and steel plate axis should not be less than 45 degrees, while the angle of not more than 70 degrees, the screw thread steel on both sides of the transverse rib of relative direction should bethe opposite;

Transverse rib and spacing L not greater than 0.7 times the nominal diameter of the screw thread steel;

Transverse rib side and screw steel surface shall not be less than 45 degreesangle;

The gap between the screw thread steel on both sides of the end of therelative transverse ribs (including longitudinal rib width) should not be greater than the nominal sum of screw thread steel perimeter 20%;

When the screw thread steel nominal diameter is less than 12mm, the relativerib area should not be less than 0.055; some nominal diameter is 14mm and 16mm, the relative rib area should not be less than 0.060; nominal diametergreater than 16mm, the relative rib area should not be less than 0.065.

The length and the allowable deviation of 3

A, length: screw steel usually according to fixed length delivery length, specific delivery length should be specified in the contract; some thread steel to coil at the time of delivery, every dish is a screw steel, allowing each batch of 5%number (less than two wheel is two disc) consisting of two screw thread steel.The wheel weight and diameter of disc by both sides provisions.

B, length tolerance: screw thread steel according to fixed length delivery length when the allowable deviation shall not exceed +50mm.

C, the bending degree and end: allergic straight thread steel bending does not affect the normal use, the total bending degree greater than the total length ofthread steel 40%; screw steel end should be cut straight, local deformationshould not affect the use. [1]

HRB400 - the need to detect project

Inspection items include: serial number of certificate, rolling furnace number,grade, chemical composition (C, Si, Mn, P, V), tensile strength, yield point,percentage elongation, relaxation rate, sectional area, product name,specifications, quantity, date of production, the implementation of standards,receiving unit etc.. Acceptance only after passing inspection will only be forrebar.