Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:25 m.t.

Supply Capability:100000 m.t./month

Product Description:

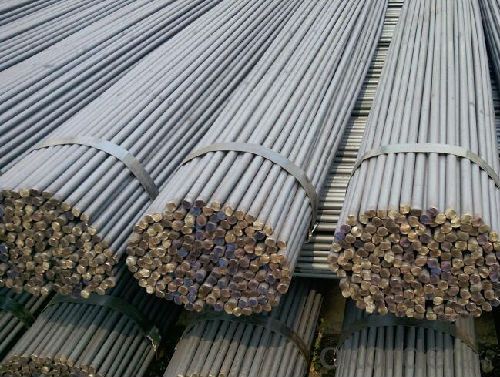

OKorder is offering hot rolled steel round bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel round bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel round bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q235, A36, SS400, S235JR

2. Feature: Unbreakable, grinding resistant and high impact value

3. Diameter: 8mm-150mm

4. Performance: Mainly for civil construction

5. Characteristics: Even hardness, no deformation, no breaking, no mal-roundness

6. Technique: Hot rolled

7. Mass: Mass (kg/m) = Diameter (mm) × Diameter (mm) × 0.00617

Usage and Applications of Steel Round Bar Products

1. Steel round bar products is used in construction and a large number of architectural and engineering structures. And it can be used in production of handrail, windows, machinery, telecom and curtain wall.

2. It can be used in the fields like metal mines, cement plants, water coal slurry, power stations and chemical industry.

3. Besides, we can supply some especial material steel round bar that can be used for main shaft of steamer, hummer shank, with big section and supper force.

4. Recommended watchcase factory, screw factory and other cold stamping products industry use.

Packaging & Delivery of Steel Round Bar Products

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of Steel Round Bar Products

Material prepare (billet) — heat up — rough rolling — precision rolling — cooling — packing — storage and transportation

Characteristics of Steel Round Bar Products

1. The steel in which the main interstitial alloying constituent is carbon in the range of 0.12–2.0%.

2. As the carbon percentage content rises, steel has the ability to become harder and stronger through heat treating; however it becomes less ductile.

3. Regardless of the heat treatment, higher carbon content reduces weld ability. In carbon steels, the higher carbon content lowers the melting point.

4. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.