Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:1 set

Supply Capability:1000 set/month

1. Introduction

HLT chemical process pump is a vertical centrifugal pump designed by referring to API610 standard.

Sealing arrangement and flushing plan recommended by API682 the 3rd edition.

2. Application

Mainly for industries of petroleum and chemical, oil depots, dyeing and printing, environmental protection, sewage treatment, as well as for water supply and drainage of tall buildings, water circulation, small-sized boilers etc.

3. Technical Data

Max operating working pressure 2.0MPa

Capacity: 3~400m3/h

Head: 7~125m

Temperature: -20~200℃

4. Materials

For wetted parts in contact with medium, the common materials are as follows:

S.S304, 316, 316L, 310Cu, 0Cr25Ni6, Alloy 20#, 904L, TA2, Ti/Pd, Ni, Monel etc.

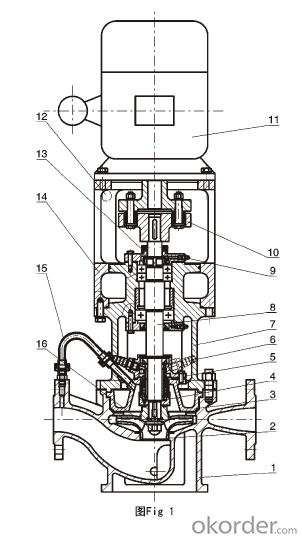

5. Pump Structure

6. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

5 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.