Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:3000 pc

Supply Capability:50000 pc/month

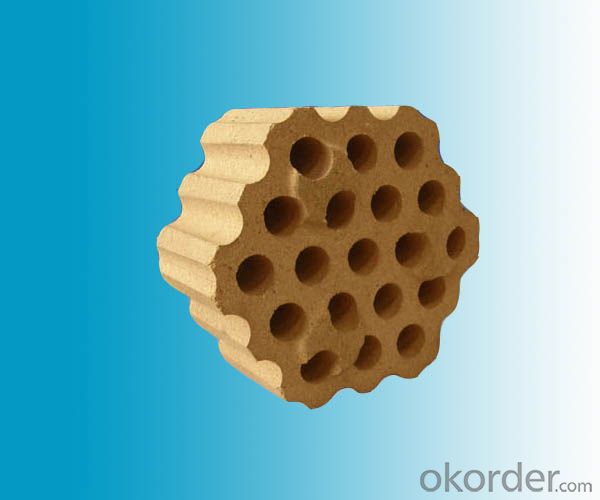

| Mainly types of refractory bricks |

1, High alumina brick, which can be used for cement kiln, rotary kiln and other high temperature kiln.

2,Magnesia carbo brick, which can be used for converter furnace, ladle and electric furnace

3,Insulating bricks, which can be used for insualting layer for high temperature furnce

4,Nozzle bricks, slide gate brick that can be used for tundish and ladle

5,Well block that used for fixing nozzle

| Advantages of types of refractory bricks |

1,All the bricks made by our own factory, which with facatory price for sure

2,Brick size can be made according to different drawing

3,Tell me bricks application, and recommendation can be provided for you.

4,Short delivery time.

| High alumina brick | |||||

Item | Index | ||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | |

Al2O3/% ≥ | 80 | 75 | 65 | 55 | 48 |

Apparent porosity/%, ≤ | 22 | 23 | 23 | 22 | 22 |

Cold crushing strength/Mpa ≥ | 55 | 50 | 45 | 40 | 35 |

0.2Mpa load softening temperature/°C ≥ | 1530 | 1520 | 1500 | 1450 | 1420 |

Permanent linear change/% | 1500°CX2h | 0.1~-0.4 | |||

1450°Cx2h | 0.1~-0.4 | ||||

1.High compression strength.

2.Top high-temperature capability.

3.Excellent thermal stability.

4.Low thermal conductivity.

5.Powerful penetrating-proof capability.

6.Good erosion-resistance.

7.Long service life.

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.