Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:-

Supply Capability:-

1,Structure of (Mineral Fiber Ceiling) Description

Mineral Fiber Ceiling

1.Size 600 x 600, 600 x 1200 mm,Thickness 7~20mm

2.Acoustics NRC 0.50

3.RH:95%

4 Free Samples,OEM

2,Main Features of the (Mineral Fiber Ceiling)

Mineral Fiber Ceiling

Size:600 x 600, 600 x 1200 mm

Thickness: 7mm 8mm 10mm 12mm, 15mm, 18mm, 20mm

Color:White

Material: Mineral Fiber, Wet-formed asbestos Free

Surface :Finished actory-applied vinyl latex paint

Fire Resistance Type: B1 GB8625-88

Light Reflect: 0.80

Acoustics NRC : 0.50

Insulation Value:1.5 btu

0.26 wat

Weight:2.70 kg/m2 with 15mm

Free Samples

Acoustic ceiling board

1.sound absorption

2.fire/moisture proof

3.size:(300~600)x(600~2400mm)x(12~20mm)

4.low density

Product: Mineral fiber acoustic ceiling board

Standard sizes:600mmx600mm/600x1200mm

24"x24"/24"x48"

Other sizes: (300-450mm)x(1200mm-2400mm)x(15mm-20mm)

(12"-16")x(48"-96")x(3/5"-4/5")

Edge detail: Angled Tegular

Beveled Tegular

Suqare Lay-in

Normal Concealed and exceed concealed

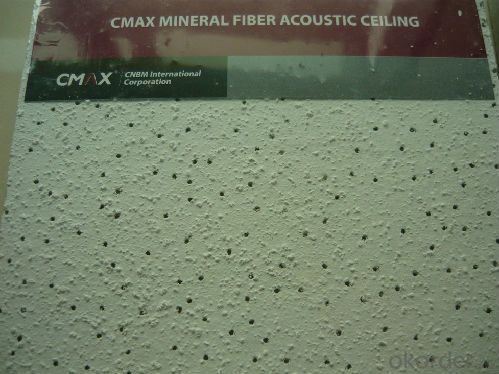

3,(Mineral Fiber Ceiling) Images

4,(Mineral Fiber Ceiling) Specification

Item | Detail |

Name | Mineral wool ceiling board/ mineral wool acoustic board/ mineral fiber board etc. |

Color | White |

Sizes | 595mm*595mm 600mm*600mm 603mm*603mmm 600mm*1200mm etc |

Thickness | 9mm-20mm |

Pattern | Pine holes,Little-Stars,Lovely Worms,Sand Surface and other special designs |

Raw material | Wet-formed mineral fiber |

Surface | Factory-applied vinyl latex paint |

Density | 280kg-420kg/m3 |

Edge finish | Square edge, tegular edge, adhesive and nails edge, concealed edge, shiplap edge, and liner shiplap edge. |

Noise reduction coefficient | NRC 0.4-0.6 |

Humidity Resistance(RH) | ≥80% |

Light reflectivity | ≥85% |

Fire Performance | non-combustible,reach class B1 according to GB8624-2006 And USD standard ASTME1264 class A |

Acoustical performance | comply with the requirements of JC/T670-2005 |

Moisture resistant | conform to the quality requirements of standard board(12mm,14mm) according to JC/T670-2005 |

Environmental protection | formaldehyde content<0.1mg/L |

Feature

| 1.High light-reflectance 2.nondirectional pattern designed ,easy installation 3.Fire-resistance 4.Adopt high quality mineral wool 5.light-weight and easy to be cut. 6.Withstand condition with relative humidity up to 99%. 7.Excellent sound absorption ability and competitive price. Excellent ability of sag-re |

5,FAQ of (Mineral Fiber Ceiling)

Surface pattern:Different designs avaliable.

Physical data

1.Raw materials:Wet-formed mineral fiber

2.Surface finish:Factory-applied vinyl latex paint

3.Fire performance :China B1 grade(meet GB8624-1997)

4.Density:3.50kg/m2 ---4.50kg/ m2 up to thickness,180kg-230kg/m3.

5.Content of Recycled material:45%~55%

6.NRC(Noise reduction coefficient): 0.55

7.CAC(ceiling attenuation class): 35

8.Light Reflectivity: Minimum 0.85

Feature

1.High light-reflectance

2.nondirectional pattern designed ,easy installation

3.Fire-resistance

4.Adopt high quality mineral wool,100% asbestos-free

5.light-weight and easy to be cut.

6.Withstand condition with relative humidity up to 99%.

7.Excellent sound absorption ability and competitive price.

8.Excellent ability of sag-resistance

Installation: When the building is dry enough and chemical gas disappears ,installation can be started.Make sure the temperature doesnt exceed 490 C and relative humility not exceed 99%.

Transportation and storage:When transporting,take care of the edge of the board.It will be better to lay the panels on dry backing-plate horizontally,about one meter away from the wall.