Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:50 set

Supply Capability:4000 set/month

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

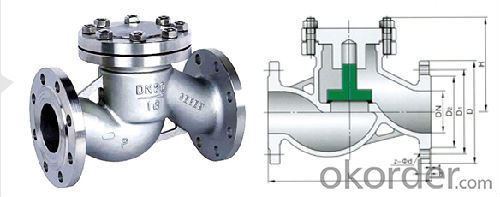

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

Product Feature:

1, the disc lift check valve disc, seat around tunnel axis rotation, due to the channel into a streamline in the valve, flow resistance is smaller than l butterfly check valve, suitable for low velocity and flow not often change the large diameter of occasions, but should not be used for oscillating flow, its sealing performance than lift.Butterfly check valve points single type, double disc type and for the most part three, the three forms mainly by the valve diameter, the purpose is to prevent the backflow medium flow or stop, decrease hydraulic shock.

2, lift check valve: disc revolve around pin in the seat of the check valve.Disc check valve has simple structure, can only be installed in horizontal pipe runs, sealing is good.

3, lift check valve: disc sliding along the center line of the body of the valve.Pipeline check valve is a new kind of valve, its small size, light in weight and good processing technology, is one of the check valve development direction.But the fluid drag coefficient is slightly superior to swing check valves.

| Main performance parameters: | |

| Nominal pressure | PN1.6/2.5/4.0Mpa |

| Suitable temperature | ≤425℃ |

| Applicable medium | Water, oil, gas, corrosive medium, etc |

| Main components | valve body, valve cover, valve, gasket |

| main material | Cast iron, ductile iron, carbon steel, stainless steel |

| Type | DN(mm) | Dimension(mm) | |||||

| L | D | D1 | D2 | z-Φd | H | ||

| HH41W-16Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 4-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 215 | 180 | 155 | 8-Φ18 | 185 | |

| 125 | 400 | 245 | 210 | 185 | 8-Φ18 | 195 | |

| 150 | 480 | 280 | 240 | 210 | 8-Φ23 | 225 | |

| 200 | 600 | 335 | 295 | 265 | 12-Φ23 | 250 | |

| 250 | 650 | 405 | 355 | 320 | 12-Φ25 | 270 | |

| 300 | 750 | 460 | 410 | 375 | 12-Φ25 | 300 | |

| HH41W-25Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 165 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 360 | 310 | 278 | 12-Φ25 | 250 | |

| 350 | 650 | 425 | 370 | 335 | 12-Φ30 | 270 | |

| 300 | 750 | 485 | 430 | 390 | 16-Φ30 | 300 | |

| HH41W-40Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 1058 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 195 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 375 | 320 | 282 | 12-Φ30 | 250 | |

| 250 | 650 | 445 | 385 | 345 | 12-Φ34 | 270 | |

| 300 | 750 | 510 | 450 | 408 | 16-Φ34 | 300 | |