Loading Port:Dalian

Payment Terms:TT or LC

Min Order Qty:20 m.t.

Supply Capability:1000 m.t./month

Welcome! As a professional intermediary, we bridge the gap between overseas buyers and China's splendid manufacturers. In collaboration with major Graphite Electrode manufacturers with 7 years of expertise in the industry, we specialize in supplying top-of-the-line graphite electrodes tailored to meet the diverse needs of our customers. Our commitment to excellence and innovation ensures that our products deliver exceptional performance and reliability across various industrial applications. Explore our range of graphite electrodes and discover why businesses worldwide trust CNBM International Corporation for their electrode needs.

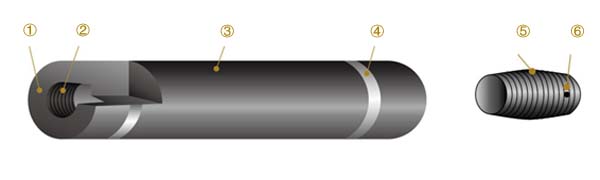

Discover our graphite electrode products through three captivating images. From electrodes to nipples and packed electrodes, each showcases our commitment to quality and precision engineering.

Graphite Electrodes

Electrode Nipples

Packaged Electrodes

Electrode End Face

Electrode Threaded Fixing Hole

Electrode Body Trunk

Electrode Caution Cordon

Tapered Electrode Nipple

Connector Pin Hole

| Test Indicator | Test Object | Unit of Measure | Regular Power - RP | High Density - HD | High Power - HP | Ultra High Power - UHP | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ø250-400 | Ø450-600 | Ø250-400 | Ø450-600 | Ø250-400 | Ø450-600 | Ø300-400 | Ø450-500 | Ø550-650 | Ø700-800 | |||

| Resistivity, max. | Electrode | μΩm | 9.0 | 9.0 | 7.0 | 7.0 | 6.5 | 6.5 | 6.2 | 6.2 | 6.0 | 5.8 |

| Nipple | μΩm | 8.0 | 8.0 | 6.3 | 6.3 | 5.5 | 5.5 | 5.0 | 5.0 | 4.2 | 4.0 | |

| Flexural Strength, min. | Electrode | MPa | 8.0 | 7.0 | 10.0 | 9.0 | 10.5 | 10.0 | 10.5 | 10.5 | 11.0 | 11.0 |

| Nipple | MPa | 15.0 | 15.0 | 17.0 | 17.0 | 18.0 | 19.0 | 20.0 | 20.0 | 22.0 | 23.0 | |

| Elastic Modulus, max. | Electrode | GPa | 9.3 | 9.3 | 12.0 | 12.0 | 14.0 | 14.0 | 14.0 | 14.0 | 14.0 | 14.0 |

| Nipple | GPa | 14.0 | 14.0 | 16.0 | 16.0 | 16.0 | 16.0 | 20.0 | 20.0 | 22.0 | 22.0 | |

| Bulk Density, min. | Electrode | g/cm3 | 1.54 | 1.54 | 1.64 | 1.64 | 1.65 | 1.65 | 1.67 | 1.66 | 1.66 | 1.68 |

| Nipple | g/cm3 | 1.72 | 1.72 | 1.74 | 1.74 | 1.74 | 1.74 | 1.75 | 1.76 | 1.78 | 1.78 | |

| CTE(100-600℃), max. | Electrode | 10-6/℃ | 2.9 | 2.9 | 2.6 | 2.6 | 2.4 | 2.4 | 1.5 | 1.5 | 1.5 | 1.5 |

| Nipple | 10-6/℃ | 2.7 | 2.7 | 2.3 | 2.3 | 2.0 | 2.0 | 1.4 | 1.4 | 1.3 | 1.3 | |

| Ash Content, max. | Electrode | % | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Nipple | % | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Nominal Diameter | Permissible Current Load (A) | |||

|---|---|---|---|---|

| Regular Power - RP | High Density - HD | High Power - HP | Ultra High Power - UHP | |

| Ø250 | 7,000-10,000 | 8,000-12,000 | 8,000-13,000 | - |

| Ø300 | 10,000-13,000 | 11,000-16,000 | 13,000-17,400 | 15,000-22,000 |

| Ø350 | 13,500-18,000 | 15,000-22,000 | 17,400-24,000 | 20,000-30,000 |

| Ø400 | 18,000-23,500 | 20,000-28,000 | 21,000-31,000 | 25,000-40,000 |

| Ø450 | 22,000-27,000 | 24,000-34,000 | 25,000-40,000 | 32,000-45,000 |

| Ø500 | 25,000-32,000 | 28,000-42,000 | 30,000-48,000 | 38,000-55,000 |

| Ø550 | 28,000-34,000 | 31,000-48,000 | 34,000-53,000 | 45,000-65,000 |

| Ø600 | 30,000-36,000 | 34,000-54,000 | 38,000-58,000 | 50,000-75,000 |

| Ø650 | 32,000-39,000 | - | 41,000-65,000 | 60,000-85,000 |

| Ø700 | 34,000-42,000 | - | 45,000-72,000 | 70,000-120,000 |

| Nominal Diameter (mm) | Actual Diameter (mm) | Nominal Length (mm) | Actual Length (mm) | |||

|---|---|---|---|---|---|---|

| Max. | Min. | Min. (Rough Spot Removed) | Tolerance | Shorter Lengths | ||

| Ø250 | 256 | 252 | 248 | RP/HP 1600/1800/2000 | ±100 | -275 |

| Ø300 | 307 | 302 | 299 | RP/HP 1600/1800/2000/2200 UHP Ø300 1600/1800 UHP Ø350 1600/1800/2000 UHP Ø(400-450) 1600/1800/2000/2200 | ||

| Ø350 | 358 | 352 | 349 | |||

| Ø400 | 409 | 403 | 400 | |||

| Ø450 | 460 | 454 | 451 | |||

| Ø500 | 511 | 505 | 502 | 1800/2000/2200/2400 | ||

| Ø550 | 562 | 556 | 553 | 1800/2000/2200/2400/2700 | ||

| Ø600 | 613 | 607 | 604 | RP/HP 2000/2200/2400/2700 UHP 2200/2400/2700/3000 | ||

| Ø650 | 663 | 659 | 656 | ±100/±150 | ||

| Ø700 | 714 | 710 | 707 | |||

Note: A "rough spot" in the context of graphite electrodes refers to an irregular or uneven surface area on the electrode, which can negatively affect its performance during use, particularly in electric arc furnaces. These spots can lead to increased wear, inconsistent electrical conductivity, and may contribute to the formation of defects in the molten steel.

Do not stack electrodes and connectors directly on the ground. Instead, place them on wooden or metal racks to prevent damage or contamination from soil. Do not discard the packaging of unused electrodes temporarily, as the packaging effectively prevents dust and debris from settling on the electrode surface or threads.

Graphite electrodes should be stored neatly in the warehouse, with both sides of the electrode stacks leveled to prevent sliding. The stacking height of the electrodes should generally not exceed 2 meters and preferably not exceed 4 layers.

Graphite electrodes should be protected from rainwater and moisture. If the electrodes become damp, they should be dried before use to prevent cracking, spalling, and increased oxidation consumption during the steelmaking process.

Do not store electrode nipple joints in high-temperature environments to prevent the melting of joint bolts due to excessively high temperatures.

Last Updated: 2024-09-25