Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:100 set/month

Profile

The crane has rotating hanging beam, suitable for steel, storage yard, warehouse, outdoor fixed span, loading and unloading steel plate, shaped steel, coil and other materials. It is especially suitable for lifting different specifications and requiring horizontal rotation. The electromagnetic sucker, clamp and other special sling can be carried under hanging beam.

Components

The Upper Rotating Hanging Beam Crane is a kind of crane which can drive the hanging beam rotation through the upper trolley rotation; the fixed electromagnet on the hanging beam to absorb and carry heavy objects. The electromagnetic hanging beam rotation angle be drove by the upper trolley is: 0~270°; it can meet the requirements of material turning, cross stacking and so on. The Upper Rotating Hanging Beam Crane is mainly composed of bridge frame, crane running, trolley, electromagnetic hanging beam, cab and electrical equipment.

-Bridge Frame

The bridge frame is the main force component of the crane. The double beam with double track structure is adopted. The main beam and the end beam are the main force parts, and the auxiliary metal structure is composed of trolley track, walking platform, railing, ladder and so on.

The main weld by submerged arc welding or gas welding; after welding, the welds are detected according to the regulations of ‘GB/T 14405 - 2011 general overhead crane’. The main force material is Q235B, and the main beam section is analyzed and calculated by finite element method to ensure that it has sufficient strength, stiffness and overall stability.

All steel plates did ball blast pretreatment, reaching Sa2.5 grade standard. The camber ratio is (0.9 ~ 1.4) S/1000, and the maximum camber position is controlled in the middle of the span 1/10. The end beam is a box structure, and the end beam is connected with the main beam as rigid connection. The end beam needs to be transported after disassembly, and it is connected by high strength bolts, and the connection plate is positioned by reaming bolts. The walking platform of bridge with 3mm thick tread plate, channels are set up for 1050mm high railing, with a distance of 350mm for horizontal bar, the bottom height of retaining plate is 100mm, any place on the railing can withstand the load of 1kN (100kgf) from any direction without plastic deformation. In order to facilitate transportation, loading and unloading, installation, the main components are equipped with hoisting lug, hoisting hole, etc., the hoisting lug, hoisting hole strength and location need to fully consider the safety and convenience of lifting.

Technical Parameters

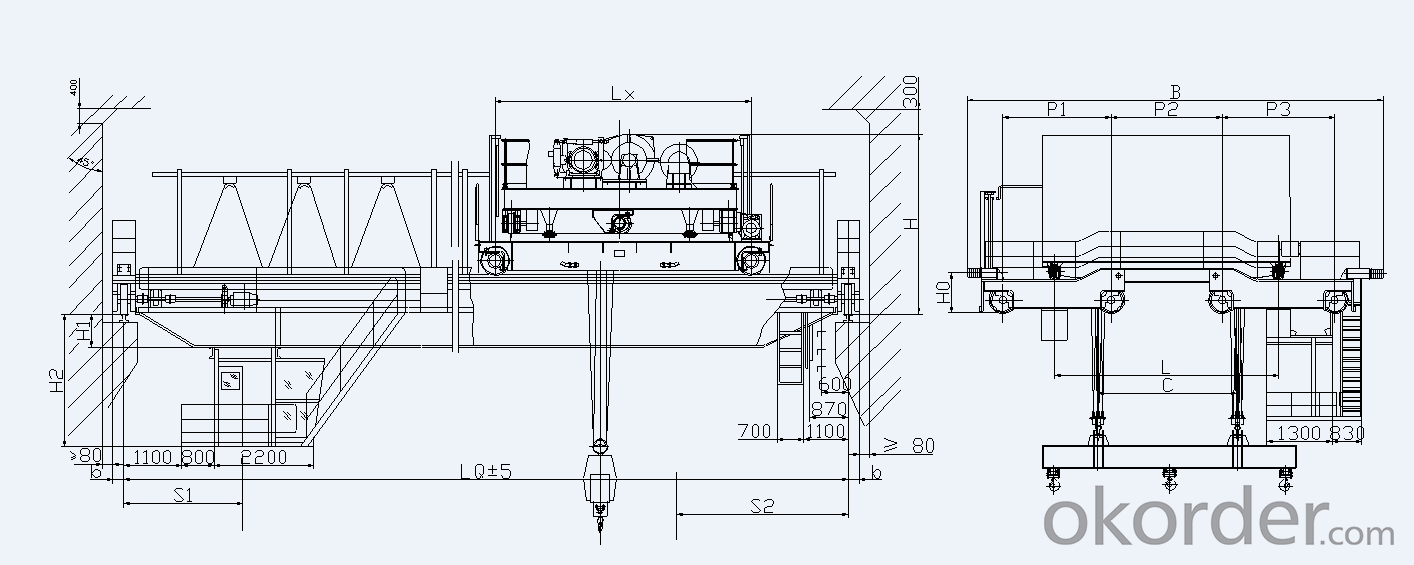

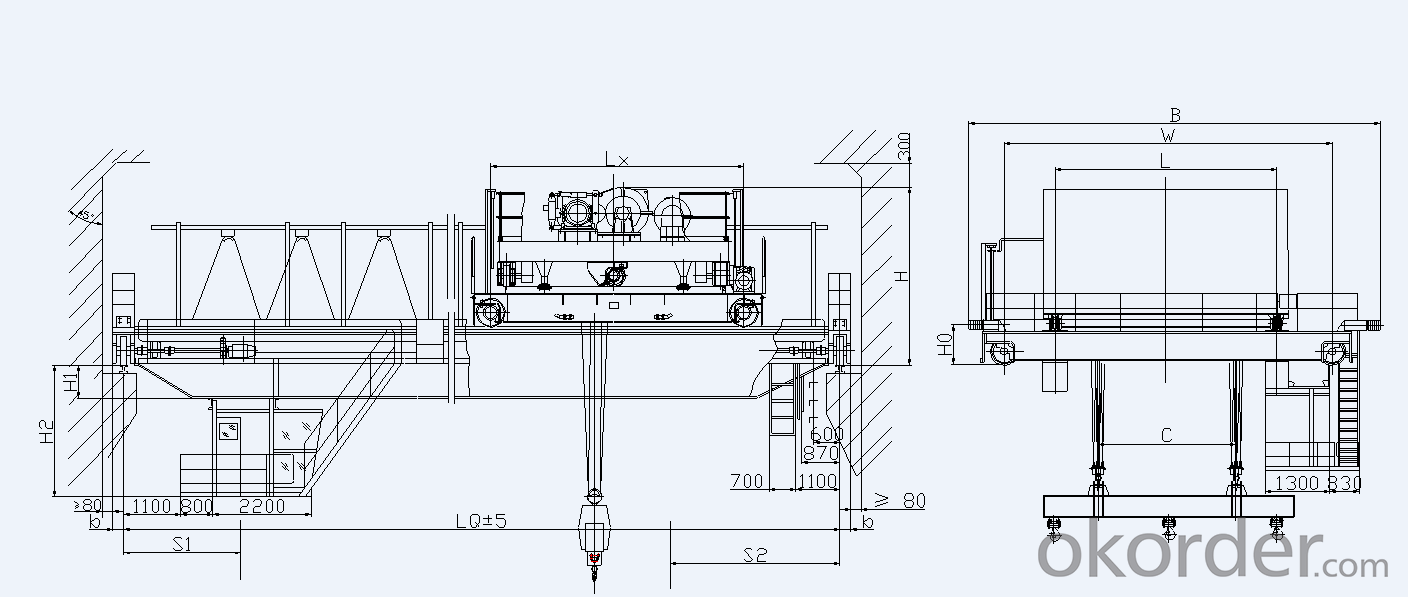

Figure2. QD(10+10)t~(25+25)t

Lifting Capacity | t | 5+5 | 10+10 | 16+16 | 25+25 | |||

Working Class | A6 | A7 | A6 | A6 | ||||

Span | m | 28.5 | 25 | 34 | 25 | 33 | 25 | |

Max. Lifting Height | 12 | 16 | 16 | 10 | 16 | 10 | ||

Speed | Hoisting | m/min | 12.4 | 12.6 | 12.6 | 14.8 | 16 | 15.4 |

Trolley Travelling | 44.2 | 42.2 | 42.2 | 39 | 48 | 40 | ||

Crane Travelling | 102 | 85.2 | 85.2 | 106 | 101 | 107 | ||

Hanging Beam Rotation | r/min | 1.5 | 1.36 | 1.36 | 1.36 | 1.85 | 1.4 | |

Main Size (mm)

| H | 3100 | 3900 | 4100 | 4200 | 4195 | 5000 | |

H1 | 692 | 600 | 754 | 750 | 804 | 820 | ||

H3 | 3112 | 3020 | 3174 | 3170 | 3224 | 3200 | ||

H0 | 760 | 1100 | 1100 | 1200 | 1300 | 1200 | ||

Lx | 5500 | 7500 | 7500 | 7500 | 7000 | 7500 | ||

B | 8700 | 10730 | 10806 | 10850 | 10798 | 11000 | ||

W | 7000 | |||||||

L | 4000 | 6000 | 6000 | 6000 | 5500 | 6000 | ||

b | 260 | 260 | 260 | 260 | 300 | 300 | ||

P1 | 2500 | 2500 | 2500 | 2500 | 1700 | |||

P2 | 3500 | 3500 | 3500 | 3000 | 4300 | |||

P3 | 2500 | 2500 | 2500 | 2500 | 1700 | |||

S1 | 2700 | 4450 | 4450 | 4450 | 4400 | 4400 | ||

S2 | 3500 | 4000 | 4000 | 4000 | 3500 | 3700 | ||

Max. Wheel Pressure | kN | 65 | 190 | 210 | 255 | 260 | 335 | |

Total Motor Power | kW | 50.2 | 114.8 | 128.8 | 151.3 | 196 | 243.5 | |

Steel Track | 43kg/m | QU80 | QU100 | |||||

Power Supply | 3-Phases AC 380V 50H | |||||||

-Trolley

The trolley is mainly composed of trolley frame, lifting mechanism and trolley running mechanism. The trolley frame has enough strength and rigidity to ensure the lifting mechanism and the running mechanism have high installation accuracy and no deformation under any working condition.

The trolley is composed of upper trolley, lower trolley and trolley accessories, in which the upper trolley is equipped with lifting mechanism and circle running mechanism; lifting mechanism is used to lift the electromagnetic hanging beam, and the circle running mechanism is used to drive the upper trolley rotation; The lower trolley is equipped with an annular track for the upper trolley and the trolley running mechanism, which can drive the upper trolley to move laterally.

Working Principle

The working principle of the upper trolley lifting mechanism is take a motor as the power source, drive two drums through the reducer, and complete the lifting of the hanging beam through the wire rope winding system.

The annular running mechanism of the upper trolley consists of a motor, a reducer, a brake, three wheel groups and three horizontal wheels, which can drive the upper trolley to rotate 270 degrees.

The running mechanism of the lower trolley is composed of four wheels as the support of the trolley, and a set of independent driving system is used to drive the trolley centrally, driving the upper and lower to do lateral movement.

FAQ

1. How to define the lifting capacity of crane?

- When the beam hanged with hook: lifting capacity=self weight of beam + self weight of electromagnet + weight of suspended object;

- When the moving pulley and the hanging beam are integrated: lifting capacity=self weight of electromagnet + weight of suspended object;

2. How to choose electromagnet?

- The choice of electromagnet is related to the hanging object, and the specific option needs to be determined by the shape, size, temperature and shape of the suspended object. Most of the hanging objects are bundled bar, square billet, steel plate and so on.

3. How to realize the rotating mechanism of the upper rotating electromagnetic hanging beam crane?

- The rotary mechanism is designed with upper and lower trolley, the lower trolley is designed with an annular track for the upper trolley to travel, and the upper trolley realizes the rotation function through the motor drive system.

4. What are the main configuration requirements of the electromagnetic hanging beam overhead crane?

- Select the hard gear reducer first, lift brake need to have manual release function, fast speed of lifting and traveling requires, higher work efficiency; if the working level is A7, the lifting motor as far as possible to avoid the use of 6 speed.

5. What are the requirements for lifting heavy objects with hanging beams?

- When the hanging beam is used, the load center deviation is not more than 0.5m.