Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 m.t.

Supply Capability:1000 m.t./month

Product Description

High Chromium Ball Mill Grinding Balls

| Application | Material comminution In cement/Mining/Power Industry |

| Size Range | 10mm-150mm |

| Chromium Percentage | 10%-26% |

| Production Standard | JC-T533-2004 and GB/T17445-2009 |

| Process Method | Cast |

| Microstructurer | M+C |

| Ball Breakage Rate Per Chamber | ≤0.5 |

Product Name | Designation | (HRC) Surface Hardness | Impact Toughness (AK J/cm2) | Microstructure | Specification(mm) |

| High Chromium Alloy Cast Grinding Balls | Cast Cr 26 | ≥59 | ≥3 | Martensite+ Carbide | Ø10, Ø12.7 ,Ø15,Ø17, Ø20 ,Ø25, Ø 30,Ø 35, Ø40, Ø50, Ø 60,Ø 70, Ø80, Ø90,Ø100, Ø110, Ø120 |

| Cast Cr 20 | |||||

| Cast Cr 17 | |||||

| Cast Cr 15 | |||||

| Cast Cr 12 | |||||

| Cast Cr 10 |

We can offer a variety of High Chromium grinding balls with different size and chromium percentage:

Size range from 10mm to 150mm

Chromium percentage from 10 to 26% ,or upon your request.

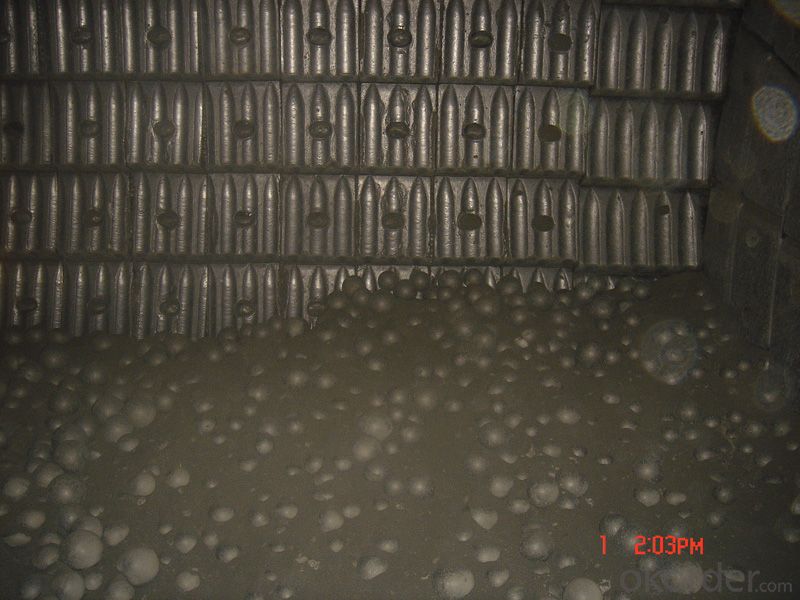

Grinding Balls Production Line

1.Sand Lined Iron Mold Casting Line,which is Applicable For Producing Grinding Balls With Diameter 40 To 150mm,Average Production Capability 2 Tonne Per Hour.

2.Flaskless Molding Casting Line:Be Suitable For Batch Production Of Casting Grinding Balls With Diameter 10 To 40mm,Casting Grinding Cylpeds With Dimension Range From 6*6mm To 40*45mm,And Even Small Castings.

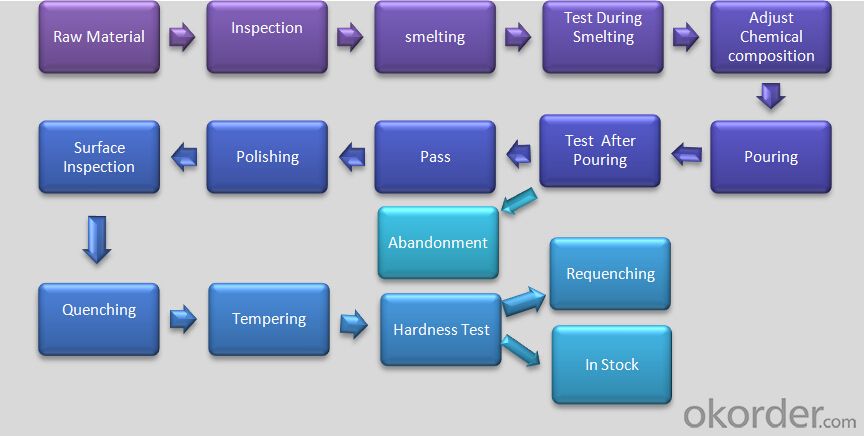

Production Process

Detailed Images