Loading Port:Qingdao Port

Payment Terms:TT or LC

Min Order Qty:25M.T. m.t.

Supply Capability:200000M.T./Year m.t./month

Type and Chemical Composition of High Chome and Low Chrome Cast Grinding Balls in Low Price and Top Quality

ID |

Name

| C | Si | Cr | Mn | S | P | Mo | Al | Microstructure |

1

| Special Hi- CrI

| 2.0-2.8 | 1.0max | 22-32 | 0.5-2.0 | 0.06max | 0.08max | micro | micro | M+C |

2

| Special Hi- CrII | 2.0-2.8 | 1.0max | 17-22 | 0.5-2.0 | 0.06max | 0.08max | micro | micro | M+C |

3

| Special Hi-Cr-III | 2.2-3.0 | 1.0max | 15-17 | 0.5-2.0 | 0.06max | 0.08max | micro | micro | M+C |

4

| High-Cr | 2.2-3.2 | 1.0max | 11-14 | 0.5-2.5 | 0.06max | 0.08max | micro | micro | M+C |

5

| Medium-Cr | 2.1-3.2 | 1.2max | 5-10 | 0.5-1.5 | 0.06max | 0.08max | micro | micro | M+C |

6

| Low-Cr | 2.2-3.5 | 1.2max | 1.5-3.0 | 0.5-1.5 | 0.06max | 0.08max | micro | micro | M+C |

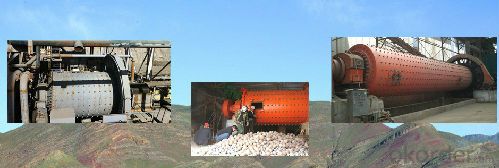

Manufacturing Process of High Chome and Low Chrome Cast Grinding Balls in Low Price and Top Quality

1.Raw material

2.Melting

3.Pouring

4.Polishing

5.Heat treatment

6.Testing

7.Qualified products (ISO CERTIFICATE)

8.Packing (steel drum, flexible container bags)