Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:1 m.t.

Supply Capability:10000 m.t./month

Description:

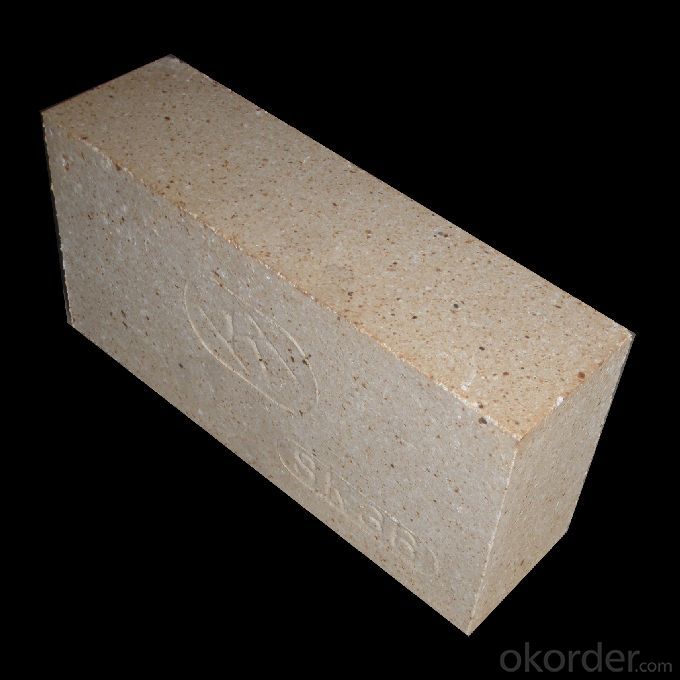

High Alumina Refractory Brick for foundry are high performance refratory products manufactured with unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity and compressive strength.

Advantages of High Alumina Refractory Brick:

High refractoriness.

Good spalling resistance and wear resistance.

Good corrosion resistance.

Good thermal shock resistance.

Applications:

High Alumina Refractory Brick is highly applied in below:

Steel furnaces

Iron making furnaces

Glass kiln

Ceramic tunnel kiln

Cement kiln

FAQ:

Payment term:T/T 30 deposit after order confirmed,the balance after goods ready before shipping,or L/C, or Western Uninon for small amount.

Lead time:Normally in 5-10 days after deposit received

Sample apolicy:Sample are always available for each modle

Shipping port: Tianjing

Technical Data Sheet:

Item | High Alumina Refractory Brick for foundry | |||

0.6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.2 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength (Mpa) ≥ | 2.0 | 2.5 | 3.0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity((W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.80 |

Max Service Temperature (°C) | 1200 | 1280 | 100 | 1350 |