Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:2 set

Supply Capability:1500 set/month

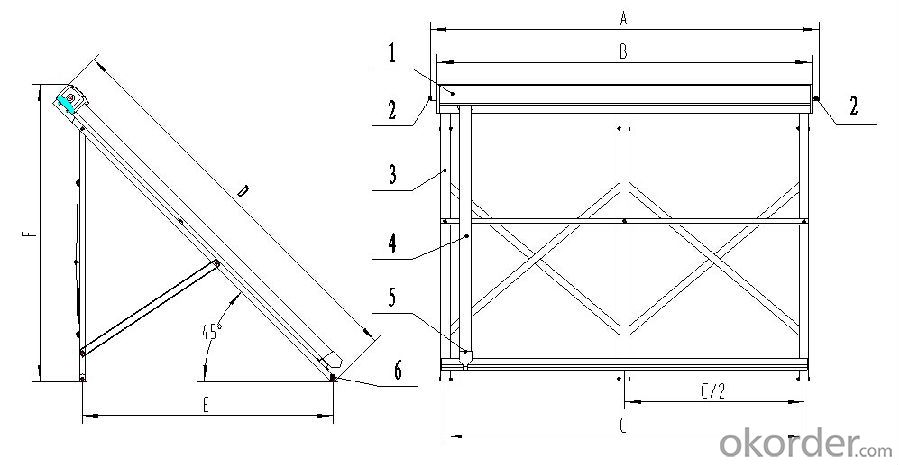

1. Structure of Heat Pipe Series for Solar Collector Model SC-H

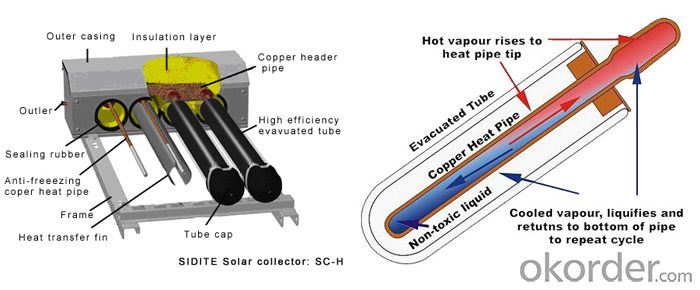

The heat pipe is hollow with the space inside evacuated, much the same as the solar tube. In this case insulation is not the goal, but rather to alter the state of the liquid inside. It seems simple to describe it, but in order to achieve this result more than 20 manufacturing procedures are required and with strict quality control.

1),Solar collector manifold : 1.1 Manifold shell, 1.2 Thermal insulation, 1.3 Inner tank;

2),Solar collector connector

3),Solar collector bracket

4),All glass vacuum tube: 4.1 Vacuum tube,4.2 Aluminum fin,4.3 Heat pipe

5),Tube holder

6),Wind feet

2. Main Features of Heat Pipe Series for Solar Collector Model SC-H

All glass vacuum insulation tube resistant to high temperature and anti-freeze

Super conducting copper heat pipe let get high heat transfer speed and start temperature low.

All aluminum alloy shell and bracket, oxidization or spraying plastics anticorrosion treatment.

Thermal Insulation layer in use high temperature, high density, and small coefficient of thermal conductivity

Inner tank by high purity and good quality brass processed, which can withstand pressure 1 Mpa

Easy for installation

3. Heat Pipe Series for Solar Collector Model SC-H Images

4. Heat Pipe Series for Solar Collector Model SC-H Specification

Model | SC-H-10 | SC-H-15 | SC-H-18 | SC-H-20 | SC-H-24 | SC-H-25 | SC-H-30 |

Type | SC-H1-10 | SC-H1-15 | SC-H1-18 | SC-H1-20 | SC-H1-24 | SC-H1-25 | SC-H1-30 |

Vacuum tube quantity(pcs) | 10 | 15 | 18 | 20 | 24 | 25 | 30 |

Tube spacing (㎜) | 75 | ||||||

Vacuum tube diameter/length (㎜) | φ58/1700 | ||||||

Vacuum tube material | high borosilicate glass 3.3

| ||||||

Vacuum tube inner/outer pipe wall thickness (㎜) | 1.6/1.8 | ||||||

Heat pipe condensing end diameter/length (㎜) | φ14/1750 | ||||||

heat pipe material/wall thickness (㎜) | Copper tp2/0.6 | ||||||

inner tank diameter/wall thickness (㎜) | φ35/1.0 | ||||||

connector size | φ22 or 3/4″ | ||||||

collector insulation material/thickness (㎜) | Rock wool/40 | ||||||

solar collector rated pressure (MPa) | 0.6 | ||||||

collector operating temperature ℃ | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

collector volume (L) | 0.69 | 0.98 | 1.15 | 1.27 | 1.50 | 1.56 | 1.85 |

collector aperture area (㎡) | 1.0 | 1.5 | 1.8 | 2.0 | 2.4 | 2.5 | 3.0 |

collector total area (㎡) | 1.56 | 2.30 | 2.74 | 3.04 | 3.63 | 3.77 | 4.51 |

referral traffic (L/min) | 0.75 | 1.13 | 1.35 | 1.50 | 1.81 | 1.88 | 2.26 |

intensity pressure (Pa) | 23.2 | 59.2 | 90.6 | 116.7 | 181.7 | 200.2 | 314.0 |

intercept efficient η0 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 |

heat loss coefficient a | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 |

collector power (W)1000W/㎡ irradiation | 620 | 870 | 1047 | 1165 | 1401 | 1457 | 1748 |

collector net weight (kg) | 38.25 | 50.75 | 59.75 | 64.75 | 79.00 | 83.35 | 98.70 |

a (㎜) | 895 | 1270 | 1495 | 1645 | 1945 | 2020 | 1395 |

b (㎜) | 800 | 1175 | 1400 | 1550 | 1850 | 1925 | 2300 |

c (㎜) | 725 | 1100 | 1325 | 1475 | 1775 | 1850 | 2225 |

c/2 (㎜) | —— | —— | —— | —— | 887.5 | 925 | 1112.5 |

d (㎜) | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 |

e (㎜) | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 |

f (㎜) | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 |

5. FAQ

1. What is the working principle of the heat pipe?

At sea level water boils at 100oC (212oF), but if you climb to the top of a mountain the boiling temperature will be less that 100oC (212oF). This is due to the difference in air pressure.

Based on this principle of water boiling at a lower temperature with decreased air pressure, by evacuating the heat pipe, we can achieve the same result.

2. How is the protection against freeze of the heat pipe?

Even though the heat pipe is a vacuum and the boiling point has been reduced to only 25-30oC (86oF), the freezing point is still the same as water at sea level, 0oC (32oF). Because the heat pipe is located within the evacuated glass tube, brief overnight temperatures as low as -20oC (14oF) will not cause the heat pipe to freeze. Plain water heat pipes will be damaged by repeated freezing.

3. Is the quantity control important to the heat pipe?

Material quality and cleaning is extremely important to the creation of a good quality heat pipe. If there are any impurities inside the heat pipe it will effect the performance. The purity of the copper itself must also be very high, containing only trace amounts of oxygen and other elements. If the copper contains too much oxygen or other elements, they will leach out into the vacuum forming a pocket of air in the top of the heat pipe. This has the effect of moving the heat pipe's hottest point (of the heat condenser end) downward away from the condenser. This is obviously detrimental to performance, hence the need to use only very high purity copper.