Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:5000 m²

Supply Capability:20000 m²/month

1.Description of Glass Wool Blanket:

Rockwool is manufactured primarily from a melt of volcanic rock. The molten rock is spun into wool and resin impregnated. Rockwool when pressed into rolls and sheets package air very well which make it an excellent and reliable insulator. All output types of Rockwool are a poor conductor of heat and sound, and therefore Rockwool is also considered an excellent and reliable thermal-acoustic insulator.

Rockwool is a mineral non-organic fibrous material of excellent and distinguished properties and characteristics. It is efficiently utilized in all fields of thermo-acoustic insulation; furthermore it is used in many industries and agricultural activities.

2.Main features of Glass Wool Blanket:

1) Heat-preservation and heat-insulation, sound absorption and noise reduction

2) Damp proof property

3) Excellent fire proof performance

4) Thermal stability, high temperature heat-stability, durability, high temperature shrinkage resistance

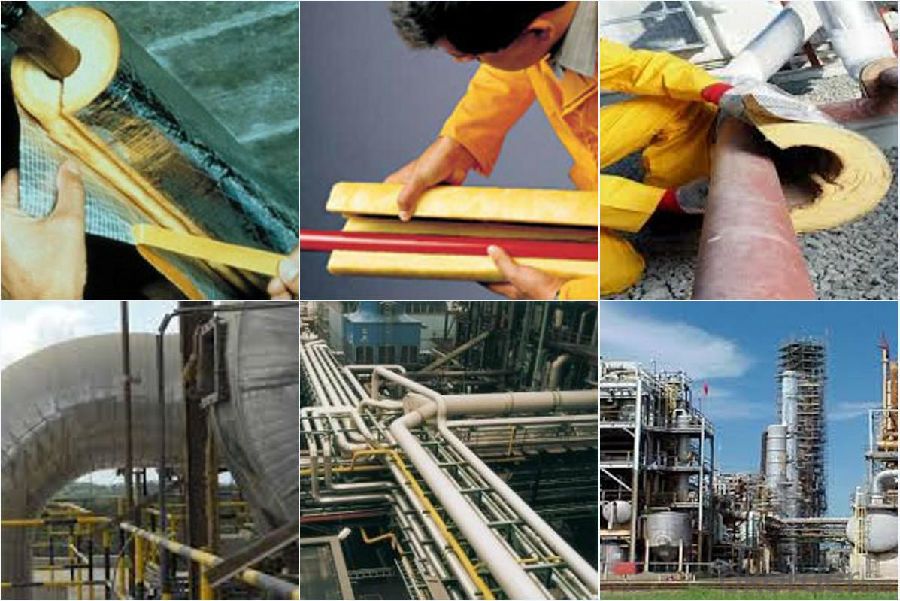

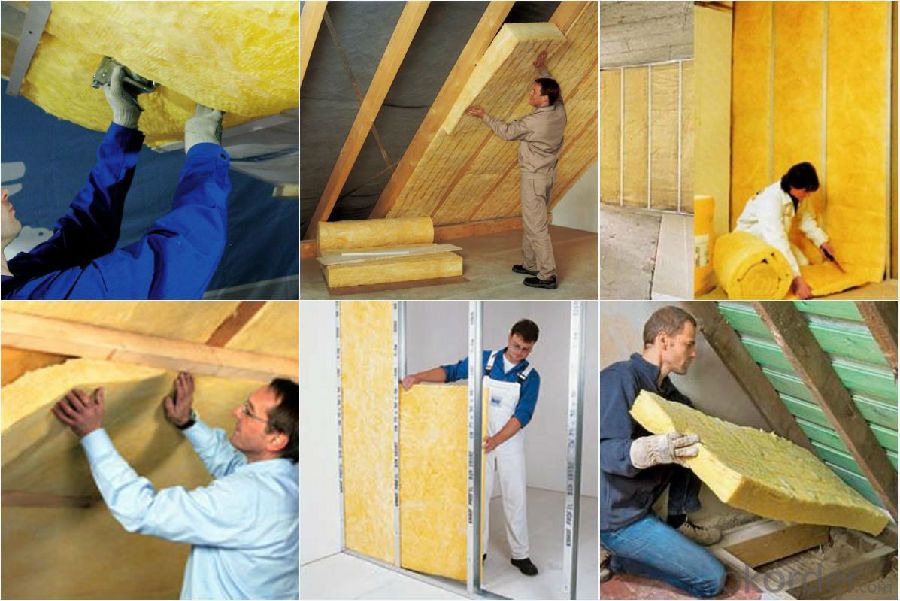

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.