Loading Port:China Main Port

Payment Terms:TT or LC

Min Order Qty:5000 Square Meters m²

Supply Capability:12000 Square Meters Per Week m²/month

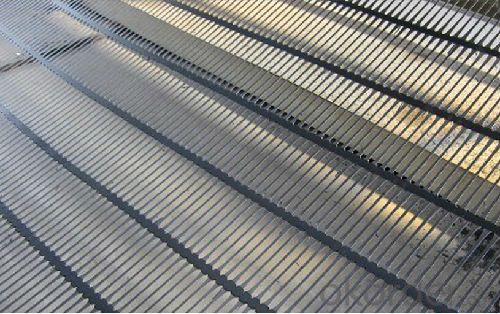

HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

1. Main Introduction of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

In grade separation applications, Uniaxial Geogrids are used to help soils stand at virtually any desired angle; from 0 to 90 degrees. Geogrids can be combined with a wide variety of facing elements in retaining wall and slope applications to produce the desired structural or aesthetic conditions for any project.

Geogrid Reinforced Soil Retaining Walls:

Geogrid reinforced soil retaining walls offer economical and aesthetically pleasing alternatives to conventional retaining wall systems. The geogrid reinforced fill zone behind the wall facing acts as a uniform mass or block, providing stability to the wall and structure. Geogrids work with a wide variety of fill materials and facing elements including segmental concrete blocks, concrete panels, geogrid wraps, timbers or boulders.

Geogrid Reinforced Slopes:

Geogrid reinforced slopes provide a natural and economical alternative to conventional concrete retaining walls. Geogrid reinforced slopes create naturally finished slope structures that are easy to construct and enhance property values because of their natural beauty. Geogrid reinforced slopes can be built at any angle to provide the most economical use of available space while avoiding the increased cost of vertical structures.

The construction of embankments, bridge approach fills, dikes and causeways over soft soils and wetlands traditionally involves expensive, time consuming construction methods. Geogrid reinforcement of these structures minimizes the project footprint, fill requirements and differential settlement, saving time and money

2. Specifications and Technical Data of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

No. | Index properties | Test Method | Item(PEUG) | ||||||

60 | 80 | 120 | 160 | 180 | 200 | ||||

1 | Polymer | _ | HDPE | ||||||

2 | Minimum Carbon Black % | ASTM D4218 | 2 | ||||||

3 | Tensile Strength @ 2% Strain MD kN/m | ASTM D6637 | 16 | 23 | 35 | 47 | 52 | 58 | |

4 | Tensile Strength @ 5% Strain MD kN/m | 31 | 44 | 65 | 85 | 104 | 116 | ||

5 | Ultimate Tensile Strength MD kN/m | 60 | 80 | 120 | 160 | 180 | 200 | ||

6 | Strain @ Ultimate Strength % | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | ||

7 | Junction Efficiency % | GRI GG2-87 | 93 | 93 | 93 | 93 | 90 | 90 | |

8 | Flexural Rigidity mg-cm | ASTM D1388 | 1,400,000 | 2,300,000 | 7,700,000 | 19,000,000 | _ | _ | |

Durability | |||||||||

9 | UV Resistance % | ASTM D4355 | 98 | 98 | 98 | 98 | 98 | 98 | |

10 | Oxidation Resistance % | EN ISO 13438 | 100 | 100 | 100 | 100 | 100 | 100 | |

11 | Brittleness | WashDOT T926 | Pass | Pass | Pass | Pass | Pass | Pass | |

Reduction Factor | |||||||||

12 | Minimum Reduction Factor for | ASTM D5262 | 1 | _ | 1.02 | 1 | _ | _ | |

13 | Reduction Factor for Creep for | ASTM D5818 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | |

Dimensions | |||||||||

14 | Roll Width m | _ | 1 | 1 | 1 | 1 | 1 | 1 | |

15 | Roll Length m | _ | 75 | 50 | 30 | 30 | 30 | 30 | |

16 | Roll Weight kg | _ | 30 | 27 | 23 | 29 | 33 | 36 | |

3. Some Photos of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

FAQ:

1. What's your payment terms?

T/T, L/C at sight

2. What's your delivery time?

Within 15days against deposit received

3/ What's your package?

WOVEN BAGS