Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:12000 pc/month

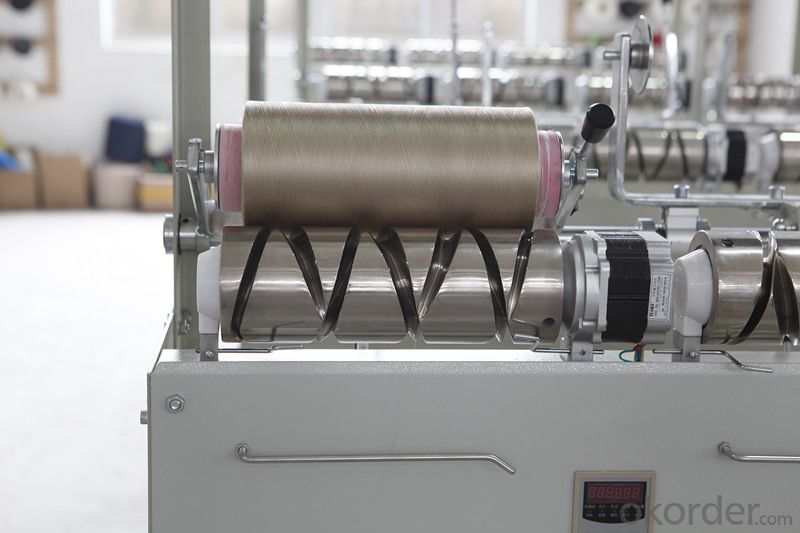

Hard Al-alloy Grooved Drum of Textile Machinery Parts

Adavantages:

1. Best groove curve,ultra-fine processing,mirror polished surface, and high smooth finish(Ra<0.4μm).

2. We plating Cr on the surface, the hardness of the surface is higher than HV900. High wear resistance, static elimination, less hairiness and surface inferior smooth processing.

3. The dynamic balance of our grooved drums are highly accurate, perform reliably,the linear velocity can reach 1200m/s.

4. Light weight and energy saving.

5. No running-in period, high quality in winding, perfect forming.

Product Description:

Pictures shows of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

Models of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Hard Al-alloy Grooved Drum of Textile Machinery Parts :

· Q:What is the machine used for?

A:Hard Al-alloy Grooved Drum of Textile Machinery Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment