Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:20 set/month

Descriptions of our tower crane:

The 2015 hot sales tower crane tc4808 features stable operation and reliable management due to the adoption of various advanced technologies. It is configured with diverse devices like the hydraulic self-propelling device, frequency converting slewing device and a series of reliable safety devices like hoisting height limiter, slewing range limiter and multifunctional limiter. It is thus easy for this heavy lifting equipment to control the hoisting capacity, load moment and trolley traveling range more precisely. Additionally, multiple electric safety devices such as anemoscopes and obstacle lights effectively prevent the breaking of trolley axles and wire ropes.

The PLC (Programmable Logic Controller) adopted by our aerial equipment can timely diagnose the cause of breakdowns. The frequency converter easily realizes continuously variable speed regulation and greatly improves the stability, reliability, and operability of the control system as well as the work efficiency of the flat top tower crane. In addition, the electric components are introduced from world-class enterprises including Omron, YASKAWA, Schneider (TE) and MEAN WELL. They ensure a low failure rate of the electric control system

Advantage of our tower crane:

1, boom relief Angle is big, greatly widened the equipment capacity and scope of work.

2, suitable for the group of tower cross homework.

3, boom stability is good, combination amplitude range.

4, suitable for height have special requirements occasions construction.

5, lifting capacity big, effectively solve the high steel structure construction team crane big lifting capacity requirements.

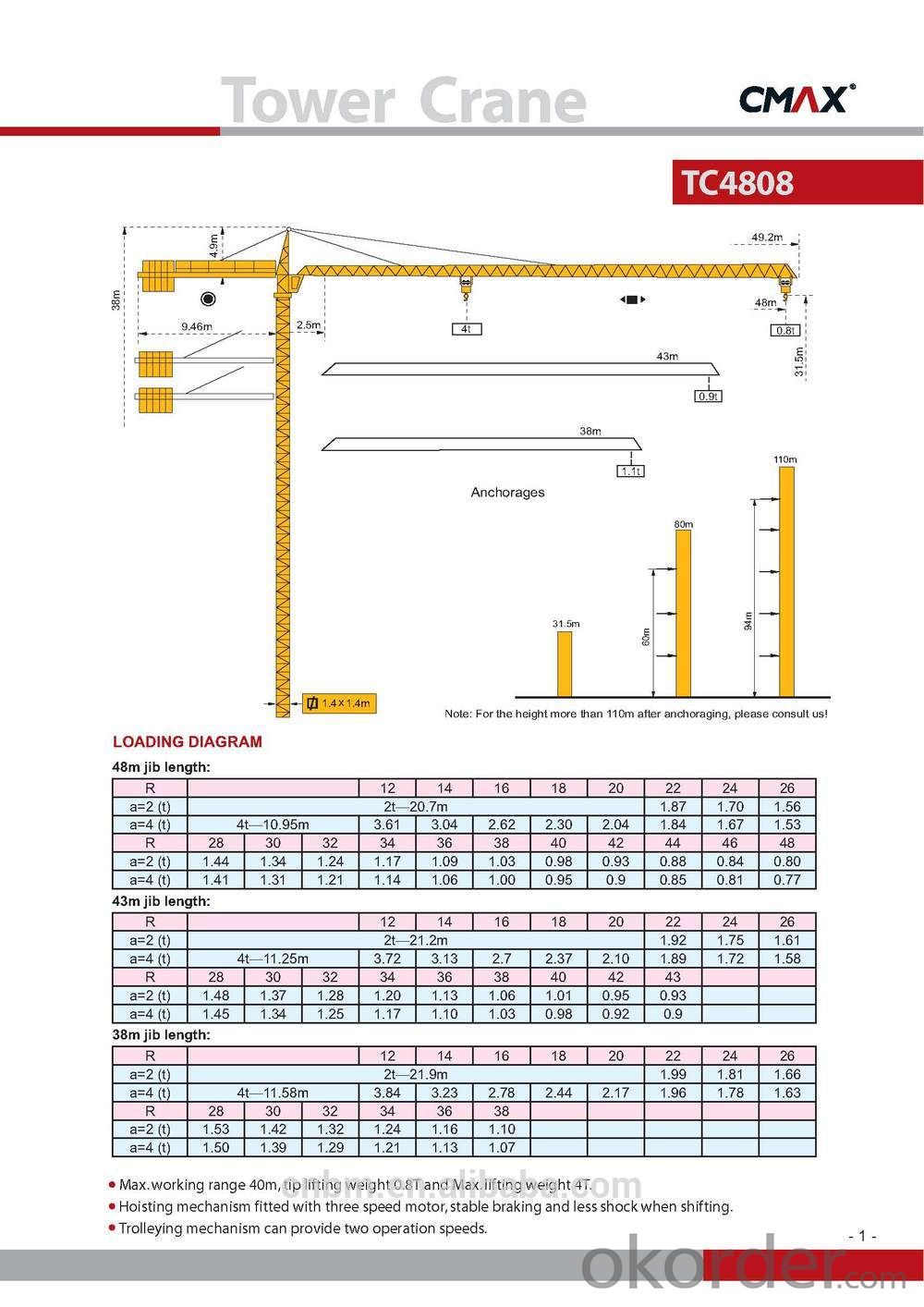

Independent height (m) | 31.5 | ||||||

Max height with attachment (m) | 110 | ||||||

Working range can be adjusted(m) | 38/43/48 | ||||||

Min working range(m) | 2.25 | ||||||

Max lifting capacity(t) | 4 | ||||||

Tip load @ 48m(t) | 0.8 | ||||||

Hoist mechanism | Falls | 2 | 4 | ||||

Lifting capacity(t) | 1 | 2 | 2 | 2 | 4 | 4 | |

Speed(m/min) | 70 | 35 | 7 | 35 | 17.5 | 3.5 | |

Motor | YZTD225M2-4/8 /32 15/15/3.5KW | ||||||

Trolleying mechanism | Speed(m/min) | 20/40 | |||||

Motor | YDEJ100-4 /8 2.4/1.5KW | ||||||

Slewing mechanism | Speed(r/min) | 0-0.6 | |||||

Motor | YD132S-6/8 2.4/1.8KW | ||||||

Climbing speed(m/min) | 0.4 | ||||||

Counterweight(t) | 7.6 | ||||||

Mast section size(L×W×H)m | 1.4×1.4×2m | ||||||

Working temperature | -40-+60°C | ||||||

Total power (KW) | 23 | ||||||

Power supply requirement (KVA) | 115KVA for generator | ||||||

Cable type ( within 30 meters from site power source to lower electric box of tower crane ) | 25mm2(3+2, 5 cores) | ||||||

Startup voltage & current | 380V×95%=361V 180A | ||||||

Rated working voltage & current | 380V 65A

| ||||||