Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:0 m.t.

Supply Capability:100000 m.t./month

| Packaging Details: | standard export wooden package or according to customers' request |

| Delivery Detail: | 15-30days after receiving your deposit |

Product Description

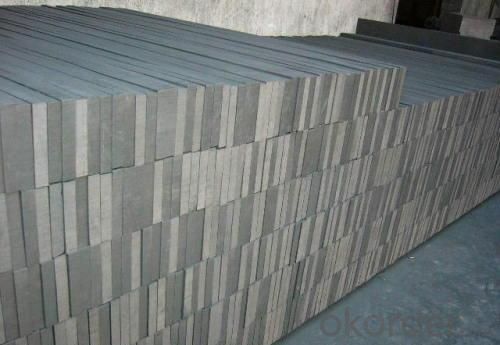

Graphite plate is made form the domestic petroleum coke and widely used in the metallurgy, machinery, electronics and chemical industry, etc. The graphite plate include molded, extruded, vibrated and isostatic. Our main and most preponderant graphite plate is molded formed. Our products own the following characteristics: low electricr esistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy and so on.

Usage

They have been used extensively in industries like solar, foundry, chemicals, electronics, ferrous metals, high-temp, heat conduction, metallurgy, lubrication, anti-corrosion .etc

1. Refractory material: widely used in the metallurgical industry.

2. Conducting material: In the electronics industry, widely used for graphite electrode, brush,, etc

3. Wear-resisting material and lubricant: Use graphite as wear-resisting and lubrication materials, can be 100m/s speed sliding in - 200 ~ 2000 °C temperature range , no or less lubricanting oil.

4. Sealing material: it can be as sealing ring in the equipment, such as centrifugal pump, hydraulic turbine ,etc.

5. Anticorrosion material: Widely used in petroleum, chemical, hydrometallurgy departments.

6. Insulation, high temperature resistant, radiation protection materials

7.Molds: hot pressing molds, static casting molds, centrifugal casting molds, pressure casting molds, fused refractory molds, etc.

8. Furnace parts: resistance heating elements, induction susceptors, structural elements and charging plates, furnace linings, heat shields and covers for pulling monocrystalline silicon or optical fibers, etc.

9. Anodes for the electrolysis of metals. As graphite elecerode plate and graphite anode plate .

10.. Parts for heat exchangers.

11. Mahince to Crucibles for melting and reduction.

Physical and chemical index

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 0.8 | 0.8 |

Density | g/cm3 | ≥1.70 | 1.73 |

Resistance | ohm | ≤8.5 | 7.5 |

Bending Strength | MPa | ≥10.0 | 11.0 |

Compressive strength | MPa | ≥24.0 | 17.0 |

Thermal conductivity | W(m.k) | ≤120 | 150 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.2 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 0.8 | 0.8 |

Density | g/cm3 | ≥1.73 | 1.76 |

Resistance | ohm | ≤8.0 | 7.0 |

Bending Strength | MPa | ≥12.0 | 12.5 |

Compressive strength | MPa | ≥31.0 | 34.0 |

Thermal conductivity | W(m.k) | ≤130 | 160 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.1 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 2 | 2 |

Density | g/cm3 | ≥1.58 | 1.60 |

Resistance | ohm | ≤11.5 | 10.5 |

Bending Strength | MPa | ≥6.0 | 6.5 |

Compressive strength | MPa | ≥18.0 | 18.5 |

Modulus of elasticity | GPa | ≤9.3 | 7.5 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.4 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 2 | 2 |

Density | g/cm3 | ≥1.70 | 1.75 |

Resistance | ohm | ≤8.5 | 7.5 |

Bending Strength | MPa | ≥9.0 | 9.5 |

Compressive strength | MPa | ≥30.0 | 31.0 |

Modulus of elasticity | GPa | ≤12.0 | 9.5 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.3 |

Ash Content | % | ≤0.3 | 0.09 |

Picture