Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:20 m.t

Supply Capability:3000 m.t/month

1.Description of Graphite Electrode for Steel Making:

Raw material: Graphite Electrode raw materials use low sulphur and low ash CPC, coke plant pitch, HP grade graphite electrode add 30% Japan needle coke, UHP grade graphite electrode use 100% Japan needle coke. They are Widely used in LF, EAF for steel making industry, Non-ferrous industry, silicon and phosphorus industry.

2.Specifications of Graphite Electrode for Steel Making:

1).Diameter:40 - 600mm or1.6"-24"

2).Length: 250 - 2400mm or10"-96"

3).Grades:RP, RPI, HP, SHP, UHP

Nipples:3-4TPI

Graphite electrodes size: dia75mm- 400mm

Our main products: all grades of graphite electrodes, such as RP, Impregnated and HP grade(over 6000MT); Anti-oxidation graphite electrodes, Male-female graphite electrodes. Also supply graphite rods, baked rods etc.

3.Applications of Graphite Electrode for Steel Making:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

4.Programmable Properties of Graphite Electrode for Steel Making:

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

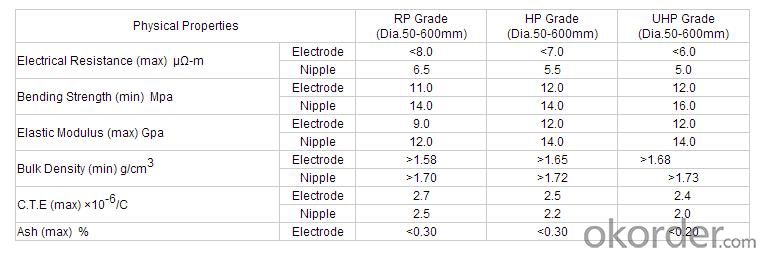

5.Technical Data of Graphite Electrode for Steel Making: