Loading Port:Tianjin

Payment Terms:TT or LC

Min Order Qty:1000 m²

Supply Capability:1000000 m²/month

Glass Wool Insulation Glass Wool Blanket Suppliers

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

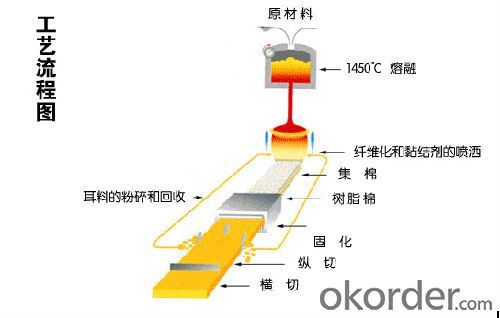

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

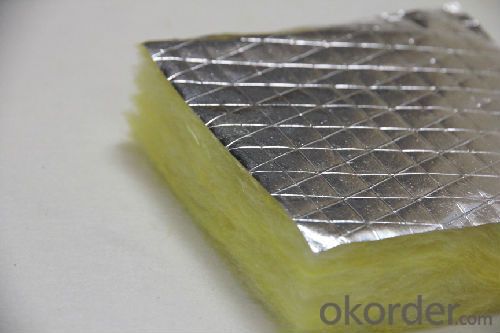

3. Glass Wool Insulation Glass Wool Blanket Suppliers Images

4. Glass Wool Insulation Glass Wool Blanket Suppliers Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.