Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:1 set

Supply Capability:10 set/month

Profile

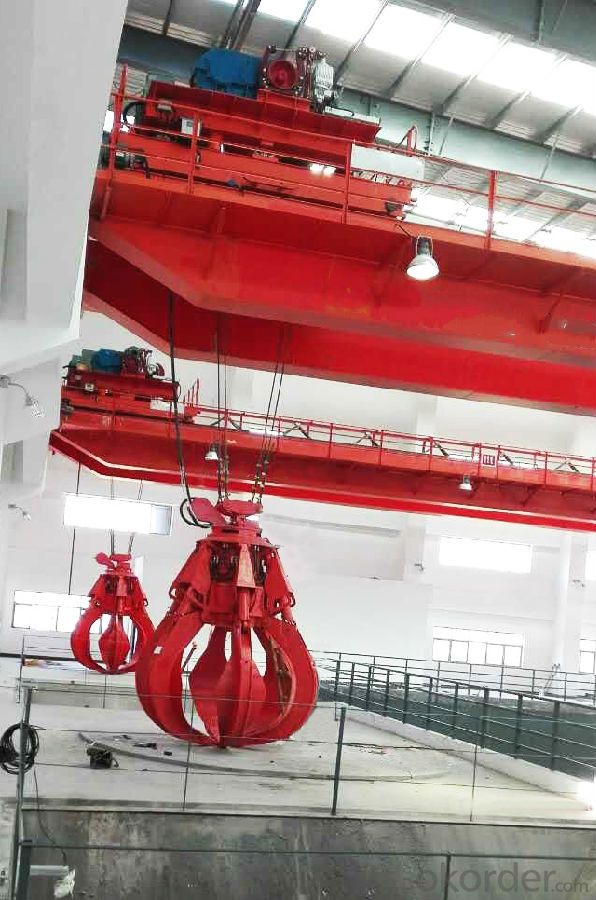

Garbage grab crane is the core equipment of garbage disposal system in various municipal waste incineration power plants, located above the rubbish storage pit,to undertake the feeding, handling, mixing, picking and weighing of rubbish. Garbage grab crane belongs to the special use overhead crane, the main components of this crane are composed of grab bucket, hoisting device, travelling device, cable hanging device, operation control device, weighing device and safety protection device, and the whole mechanism is operated in a fixed operating room.

The Garbage grab crane can perform strict lifting and transport operations to ensure the normal operation of the waste incineration power plant, and the crane can realize manual, semi-automatic, automatic control.

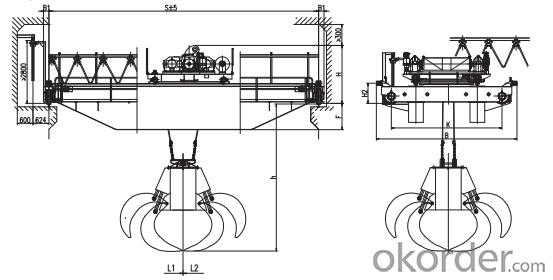

Overall Drawing

Technical Specification

Productivity | t/d | 800 - 1000 | 1000 - 1200 | 1200 - 1500 | ||||||||||||

Capacity | t | 8 | 10 | 12.5 | ||||||||||||

Volume of Grab | m³ | 5 | 6.3 | 8 | ||||||||||||

Span | m | 22.5 | 25.5 | 28.5 | 31.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |

Lifting Height | 34 | 36 | 36 | |||||||||||||

Working Class | A8 | A8 | A8 | |||||||||||||

Speed | Lifting | m/min | Up 4.5 - 45 | Up 4.5 - 45 | Up 5 - 50 | |||||||||||

Down 6 - 60 | Down 6 - 60 | Down 7 - 65 | ||||||||||||||

Trolley Travelling | 4.5 - 45 | 4.85 - 48.5 | 5 - 50 | |||||||||||||

Cart Travelling | 4.8 - 48 | 6.5 - 65 | 7 - 70 | |||||||||||||

Limit Dimension | L1 | mm | 2600 | 2600 | 2850 | |||||||||||

L2 | 2600 | 2600 | 2850 | |||||||||||||

h | 6000 | 6000 | 6000 | |||||||||||||

Main Dimension | H | mm | 2300 | 2375 | 2550 | |||||||||||

B | 5724 | 5724 | 5875 | |||||||||||||

K | 2500 | 2500 | 2650 | |||||||||||||

B1 | 230 | 230 | 230 | |||||||||||||

F | 618 | 718 | 818 | 968 | 643 | 743 | 843 | 845 | 995 | 575 | 655 | 757 | 907 | 1057 | ||

Max. Wheel Loading | KN | 117 | 125 | 134 | 141 | 136 | 143 | 151 | 162 | 170 | 155 | 165 | 175 | 185 | 195 | |

Total Power | kw | 106 | 135 | 190 | ||||||||||||

Steel Rail | 43kg/m | QU70 | 50kg/m or QU70 | |||||||||||||

Power Supply | 3-Phase AC 50Hz 380V | |||||||||||||||

Production Structure

Trolley frame separated two layers with upper and lower structure, electronic weighing sensor, stop means and a safety protection device are set between the two layers of frames; the lower frame mounting trolley operating mechanism, and the upper frame mounting hoisting mechanism. All the trolley operation is driven by three in one structure, lifting mechanism adopts frequency conversion motor + hard toothed surface reducer + hydraulic brake + double wire rope reel design, four rope double drum V shape down rope structure to avoid grab spinning and swinging.

The ‘anti swing automatic precision positioning control technology which is independent R&D by our company is the world’s first, fills the technical gap in this field. The anti swing function of this technique makes the loads swing range of crane reduce more then 95%(after actual measurement, the swing angle is less than 0.2 degrees); The automatic precision positioning control function of this technique’s control accuracy is 2 millimeters. The advantages of ‘anti swing automatic precision positioning control technology’ are as follows:

- Eliminate the time when the waiting load swinging stop, it makes the efficiency of the crane is increased by more than 30%.

- It can improve the safety of crane operation and reduce the risk of injury to staff in the hoisting and the operating area.

- Makes the crane fully automated, realize automatic grab and open up material from fixed point.

- Improve the safe running speed and further improve the working efficiency of the crane.

- Make the crane easy to operate, reduce the training time and the labour intensity of staff.

- Increase safety working space of crane.

- Prolong the crane mechanical service life.

Function

-High wear resistance

When the cable been coiled and uncoiled in drum it will produce strong friction , the tensile

strength of cable’s outer sheath should be 22-35MPA for enough to withstand long time friction

without damaging the drum.

- Water resistance and corrosion resistance

There may produce water or corrosive liquids when the cable been coiled and uncoiled in drum, cables needs sufficient performance to resist water and corrosion.

Electric hydraulic grab for garbage grab crane depends on the electric hydraulic system which is carried by itself to complete the opening and closing operation, it adopts electrical hydraulic, mechanical technology and system to design. Electric hydraulic grab is specially used for bulk, granular and irregularly shaped bulk material such as coke, pig iron, scrap steel, slag, rubbish, waste rock and so on.

Different with general overhead crane

Compare with general overhead crane which be used to hoist and grab single material, the garbage grab crane not only hoisting and grabbing unshaped domestic garbage, also according to the requirements of the waste incineration process to stir the garbage, partition stacking and do preliminary fermentation of the garbage in garbage storage pit.