Loading Port:Qingdao

Payment Terms:TT OR LC

Min Order Qty:100 m.t.

Supply Capability:300000 m.t./month

| Standard: | AISI, ASTM, DIN, GB, JIS | Grade: | 400 series | Thickness: | 0.25-2.0mm |

| Place of Origin: | Guangdong, China (Mainland) | Brand Name: | Baosteel, Tisco, Jisco, Lianzhong | Model Number: | SUS430 |

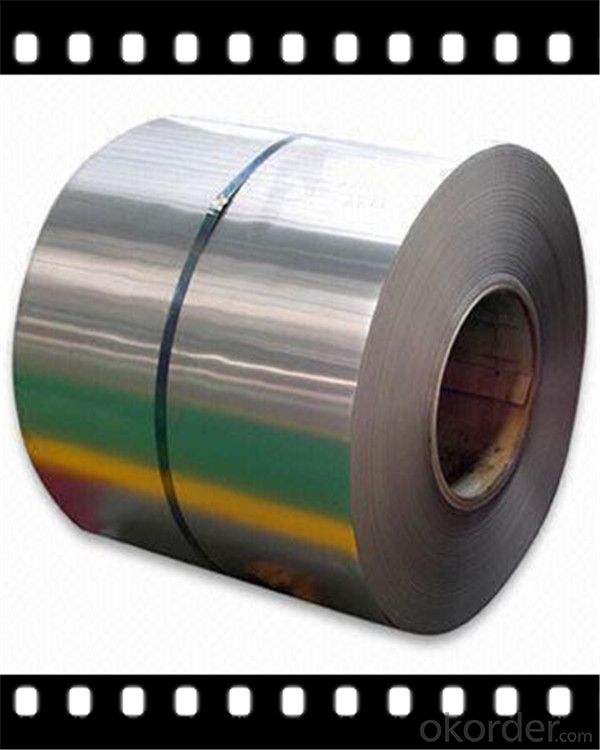

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA, HL, NO.4, Mirror |

| Application: | Utensils, kitchenware, cutlery, pots & bowls, sinks, gas stove etc. | Width: | 800-1300mm | Length: | As requested |

| Product name: | ASTM 430 Cold Rolled Stainless Steel Coil | Steel type: | Ferrite stainless steel | Cr content: | 16%-18% |

| Edge: | Mill edge/ Slitting edge | Hardness: | From full hard to DDQ | Packing: | standard export packing or as requested |

| Sample: | Available | Form available: | coil/ plate / strip/ sheet | Market: | Asia, Mid East, South America etc. |

| ODM/OEM: | Welcome |

| Product name | Galvanized Steel Coil Build Material/Pipes and Tubes Material |

| Grade | 400 series |

| Type | Steel coil |

| Standard | AISI,ASTM,DIN,GB,JIS |

| Thickness | 0.25mm-2.0mm |

| Width | 800-1300mm |

| Surface finish | BA, 2B, HL, No.4 |

| Edge | Mill edge/ slitting edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, cutlery, pots & bowls, sinks, gas stove, food industry etc. |

| Products packing | Standard export package, PVC film with wooden pallet |

| Payment terms | T/T, 20% deposit in advance, balance against copy of B/L. |

| Delivery time | 15-30 days after receiving the deposit |

CHEMICAL COMPOSITION % : | ||||||||||

GRADE | C | Si | Mn | P | S | Cr | Mo | Ni | N | Ti |

SUS430 | ≤0.12 | ≤1.00 | ≤1.00 | ≤ 0.04 | ≤ 0.03 | 16.00-18.00 | / | ≤0.75 | / | / |

SUS410S/ | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 11.50-13.50 | / | ≤0.6 | / | / |

409L | ≤0.03 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 10.50-11.75 | / | ≤0.6 | / | 0.08-0.75 |

| MECHANICAL PROPERTIES (ANNEALED) | ||||||

| ITEM NO. | GRADE | 0.2% Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) | Hardness (HRB) |

| RX-SS400-1 | SUS430 | ≥205 | ≥450 | ≥22 | ≤200 | ≤89 |

| RX-SS400-2 | SUS410S | ≥205 | ≥415 | ≥20 | ≤200 | ≤89 |

| RX-SS400-3 | 409L | ≥275 | ≥415 | ≥20 | ≤200 | ≤92 |

| SURFACE | PROCESSING METHODS | APPLICATIONS |

| BA | Those processed with bright heat treatment after cold rolling | Kitchen utensils, Electric equipment, Building construction etc. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or ther equivalent treatment and lastly by skinpass to give appropriate luster | Medical equipment, Food industry, Building construction, Kitchen utensils etc. |

| No.3 | Also known as griding. It is applied by using 100-120 grit abrasives. | Kitchen utensils, Buliding construction etc. |

| No.4 | Also known as brushed or satin finish. It is characterized by fine poslishing grit lines that are uniform and directional in appearance. It is produced by polishing the metal with a 150–180 grit belt or wheel finish. | Kitchen utensils, Building construction, Appliances, Medical equipment etc. |

| HL | It is produced by polishing the metal with a suitable grit abrasives to create continuous polishing streaks | Building construction, Elevator etc. |

| No.1 | The surface finished by heat treatment and pickling after cold rolling. The finishing is coarse in appearance. | Tank, Chemical devices etc. |

Packaging: Standard Export Packing, PVC film with wooden pallet.

Shipping: Sea transportation

Coil weight: as requested.

( Maximum load per 20GP container: 27 tons)

FAQ:

What are the advantages of your products?

1. Competitive price:

We produce resin and paint by ourself, which greatly reduce our cost!

Yes, we produce the paint! That is specially designed for steel coating. Our paint is not the cheap kind. It's performance can undoubtedly be compared with Akzonobel, KCC, Noppin....etc. You don't believe? Come and test it!

2. Products Accuracy:

We have a technician team of 40 people and a QC team of 30 poeple, ensure our products is exactly what you want.

We have clean and big lab room, equiped with modern machine for testing and improving every aspect of color steel's performance.

3. Materials:

All color Steel Sheets are made of high-quality raw materials.

We never use

a. secondary metal sheet

b.defected metal sheet

For every coil, we check their zinc coating, their evenness,their T.S,Hardness......We know unqualified products will ruin our reputation!

4.Certificate:

Our products are certified by TUV, ISO9001:2008,ISO14001:2004 etc. Our company is certified by BV company.

5. Productivity:

We have three large-scale production line, to guarantee all your orders will be finished in earlist time.

So far, we never disppoint our customer by our delivery time!