Loading Port:China Main Port

Payment Terms:TT or L/C

Min Order Qty:5 ton m.t

Supply Capability:1000 Tons Per Mouth m.t/month

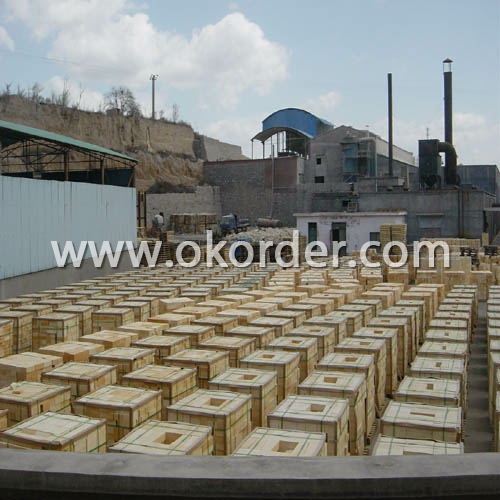

General Information Fused Cast Brick-MS36

CMAX fused cast brick-MS36 (alumina, zirconia and silica) firebricks are mainly categorized into 33#, 36# and 41# according to different zirconia's contents from 33% to 41%. Featuring huge volume density, high compressive strength, good thermal stability and strong impact resistance. It can be made into any specification defined by users to fit for different demands. It also has the capacity of maintaining excellent mechanical behavior under high temperature,

Fused Cast Brick-MS36 | ||

Physical Properties: |

|

|

Bubbling Tendency(1300℃×10hrs) | % | 2 |

Apparent Porosity, % | % | ≤1 |

Cold Crushing Strength | Mpa | ≥300 |

Exudating Temperature of Glass Phase | % | ≥1400 |

Anti-corrosion Rate of Glass Liquid(1500℃×26hrs) | % | 1.4 |

Density | g/cm3 | ≥3.85 |

Chemical Analysis: |

|

|

Al2O3 | % | ≥49 |

ZrO2 | % | ≥35.5 |

SiO2 | % | ≤13 |

Na2O+K2O | % | ≤1 |

Note: | ||

Features of Fused Cast Brick-MS36

High refractoriness

Excellent resistance to corrosion of molten glass

Excellent thermal stability

Application of Fused Cast Brick-MS36

CMAX fused cast brick mainly used in:

Glass furnace