Loading Port:Qingdao

Payment Terms:TT or LC

Min Order Qty:25M.T. m.t.

Supply Capability:150,000M.T. m.t./month

Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

1. Features for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Size: 20mm-150mm(Dia0.75''-Dia6'')

Hardness: HRC60-HRC65

Low Breakage Rate<0.5%

Impact Toughness>12J/cm2

Endurance Test>10000times

Good Wear Resistant

2. Chemical Composition for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Brand | Grade | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-3 | 65Mn | 0.6-0.7 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | 0.03max | 0.03max |

CMAX-5 | Rail IronⅠ | 0.5-0.65 | 0.60-1.0 | 0.15-0.37 | 0.25max | 0.04max | 0.04max |

CMAX-6 | Rail IronⅡ | 0.60-0.8 | 0.90-1.2 | 0.20-0.40 | 0.20-0.8 | 0.07max | 0.03max |

3. Weight and Microstructure for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT | Microstructure |

25mm/1'' | +1.5,-0.5 | 0.064 | 15625 | M+B+C (M-Martensite;B-Bainitic;C-Carbide) |

30mm/1.25'' | +1.5,-0.5 | 0.11 | 9090 | |

40mm/1.5'' | +2.0,-1.0 | 0.26 | 3846 | |

50mm/2'' | +2.0,-1.0 | 0.51 | 1961 | |

60mm/2.5'' | +3.0,-2.0 | 0.89 | 1124 | |

70mm/2.75'' | +3.0,-2.0 | 1.4 | 714 | |

80mm/3.25'' | +3.0,-2.0 | 2.1 | 476 | |

90mm/3.5'' | +3.0,-2.0 | 3 | 333 | |

100mm/4'' | +4.0,-3.0 | 4.1 | 244 | |

110mm/4.5'' | +4.0,-3.0 | 5.47 | 283 | |

120mm/4.75 | +4.0,-3.0 | 7.1 | 141 | |

130mm/5'' | +4.0,-3.0 | 9.02 | 111 |

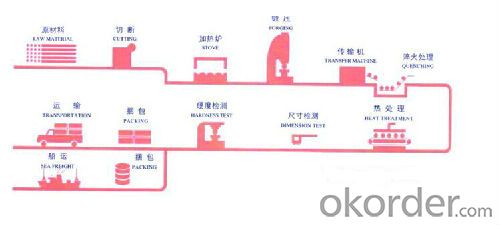

4. Production Process for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

5. Packing Ways for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008