Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:10 set

Supply Capability:100 set/month

| Packaging Detail: | Standard Export and Sea-worthy Plywood Case |

| Delivery Detail: | 30 Days |

NPS 2"~36"

ANSI CLASS 150~2500

MATERIAL: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

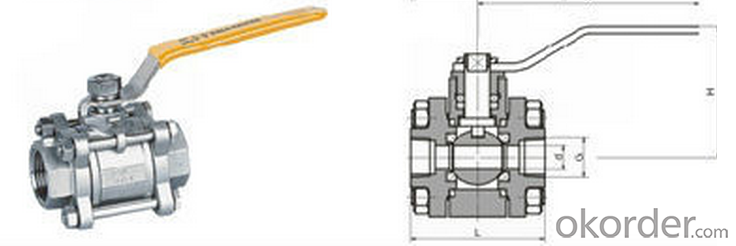

Trunnion Ball Valve

NPS 2"~36"

ANSI CLASS 150~2500

MATERIAL: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

DESIGN STD: API 608, API 6D, BS 5351

FACE TO FACE STD: ASME B16.10, API 6D

END CONNECTION STD: ASME B16.5, ASME B16.47, ASME B16.25

TEST STD: API 598, API 6D, BS 6755

1.Anti-fire safe design.Anti-static device

2.Free leakage of body Sealed construction

3.Double block&bleed.

4.Extension stem.

1.Bow-out proof stem

For the purpose of preventing the stem from flying off resulting in abnormal rising of the inner pressure of valve,shoulder is fixed at the lower part of the stem.In addition,in order to prevent leakage resulting from burnout of packing set of the stem in a fire,thrust bearing is set at the contact position of the shoulder at lower part of the stem and valve body.Thus an inverse seal seat is formed which will prevent leakage and avoid accident.

2.Anti-fire safe design

When the trunnion ball valve be used normally,its sealed by seat and ball surface,seat retainer sealed by O-ring and body,this is soft sealed and reliable sealing.When the seat and O-ring are burnt,the seat retainer and body will be sealed by expanded graphite.Thus act anti-fire safe purpose.

3.Anti-static device

In order to prevent friction among ball,stem and PTFE that generates static electricity which may light the combustibles and explosives that cause an accident,in this ball valve,static-conduction spring is set between the stem and the ball,the stem and the body.Thus static electricity is conducted to ground and system safety is secured.

4.Free leakage of body Sealed construction

The connective position of valve body and bonnet is double sealed by gasket and O-ring,on this base,such factors as fire,high temperature,shock and uneven opening or closing of the torque all can't induce external leakage.

5.Low torque in operation

The self-lubricated bearings are installed at the friction of stem,resulting in wear resistance,fiexibility of operation and low torque.

6. Double block&bleed(DBB)

When ball is full open or close position,the transmitter substance in center cavity of body can be released by drainage and emptying devices.In addition,the over loaded pressure in the center cavity of valve can be released to low pressure end by self relief seat.

7.Emergency sealing

Compound injection holes are designed and compound injection valves are installed at locations of stem/cap and body support of side valve.When sealing of stem or seat is damaged to induce leakage,the compound can be used to do the second time sealing.A concealed check valve is installed in side of each compound injection valve to prevent compound from out flowing due to the action of transmitter substance.The top of the compound injection valve is the connector for fast connection with compound injection gun.

8.Extension stem

For the underground installed valve,the stem can be lengthened and for the convenience of operation the corresponding compound injection nozzle and drainage valve can be extended to the top of valve.

9.Automatic body cavity relief

When the body pressure going up un-normally as the unstable factor,the trunnion ball valve downstream seat will be pushed by un-normally pressure,and the release the unnormal pressure automatically,it doesn't damage to the sealing of upstream seat.

10.Various driving types

The top pad of valve designed according to ISO 5211,which is convenient for connection and exchange of various drivers.The common driving types are manual,electrical,pneumatic and pneumatic/hydraulic.

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.