Loading Port:China main port

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:100000000 pc/month

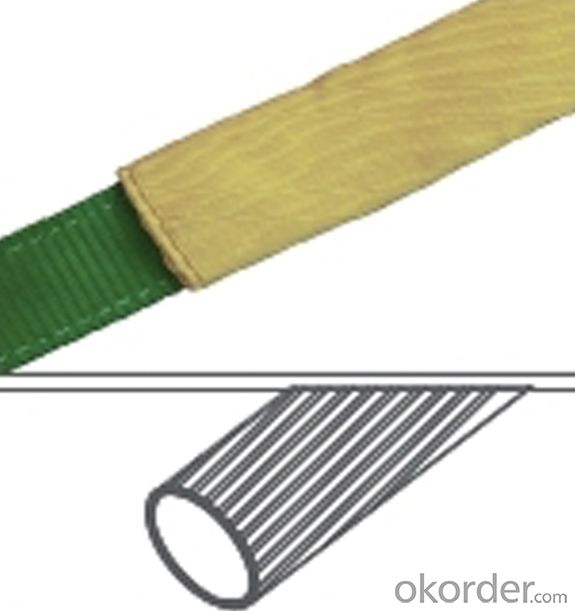

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

Certification: GS, CE, ISO

Customized support: OEM, ODM

Application: Lifting Goods

Safety factor: 5:1 6:1 7:1 8:1

Length: Customized Length

Width: Customized Width

Standard: CE/GS/ISO9001

Packing: Customers Requiement

MOQ: 1 Piece

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

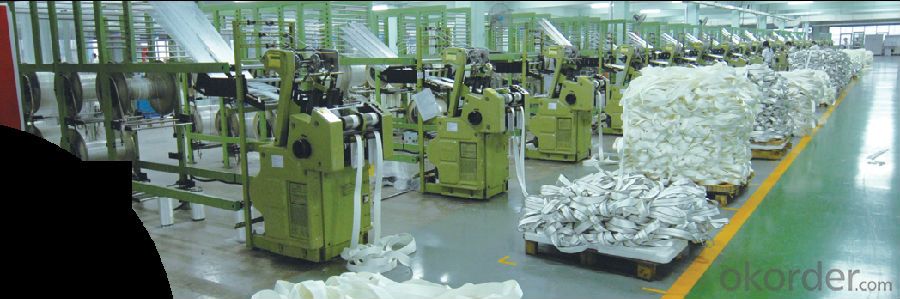

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".