Loading Port:Shanghai

Payment Terms:TT or LC

Min Order Qty:5000 kg

Supply Capability:100000 kg/month

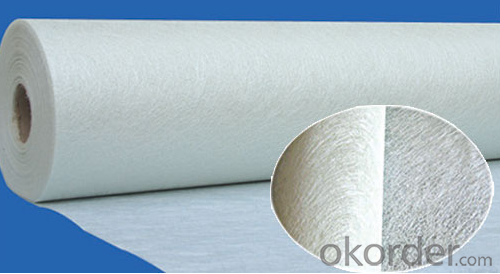

Structure of FIBERGLASS SANDWICH FABRIC COMPLEX MAT Description:

It is the multi-layered combination mat .It consists of a PP core sandwiched between chopped glass fibers and stitch together, which is used for boat making. As usual, the area weight of PP core is 150g/m2 or 250g/m2 and area weight of chopped glass fibers is 300g/m2, 450g/m2 or 600g/m2.

Main Features of the FIBERGLASS SANDWICH FABRIC COMPLEX MAT

◎ This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in closed mould applications for vehicle bodies and panels, marine (boat hulls and decks), windmill nacelles, leisure vehicle and structural shapes.

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish.

◎ low resin-consumption and faster wet-out.

◎ Good manufacturability and mechanical properties

◎ Improved fatigue and impact resistance

◎ Good drapability for complicated shapes and good resin flow

FIBERGLASS SANDWICH FABRIC COMPLEX MAT Images

FIBERGLASS SANDWICH FABRIC COMPLEX MAT Specification

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Packing:

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ of FIBERGLASS SANDWICH FABRIC COMPLEX MAT

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.