Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:100 pc

Supply Capability:80000 pc/month

PRODUCT DESCRIPTION

FRP Fitting, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact

molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

FEATURES

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

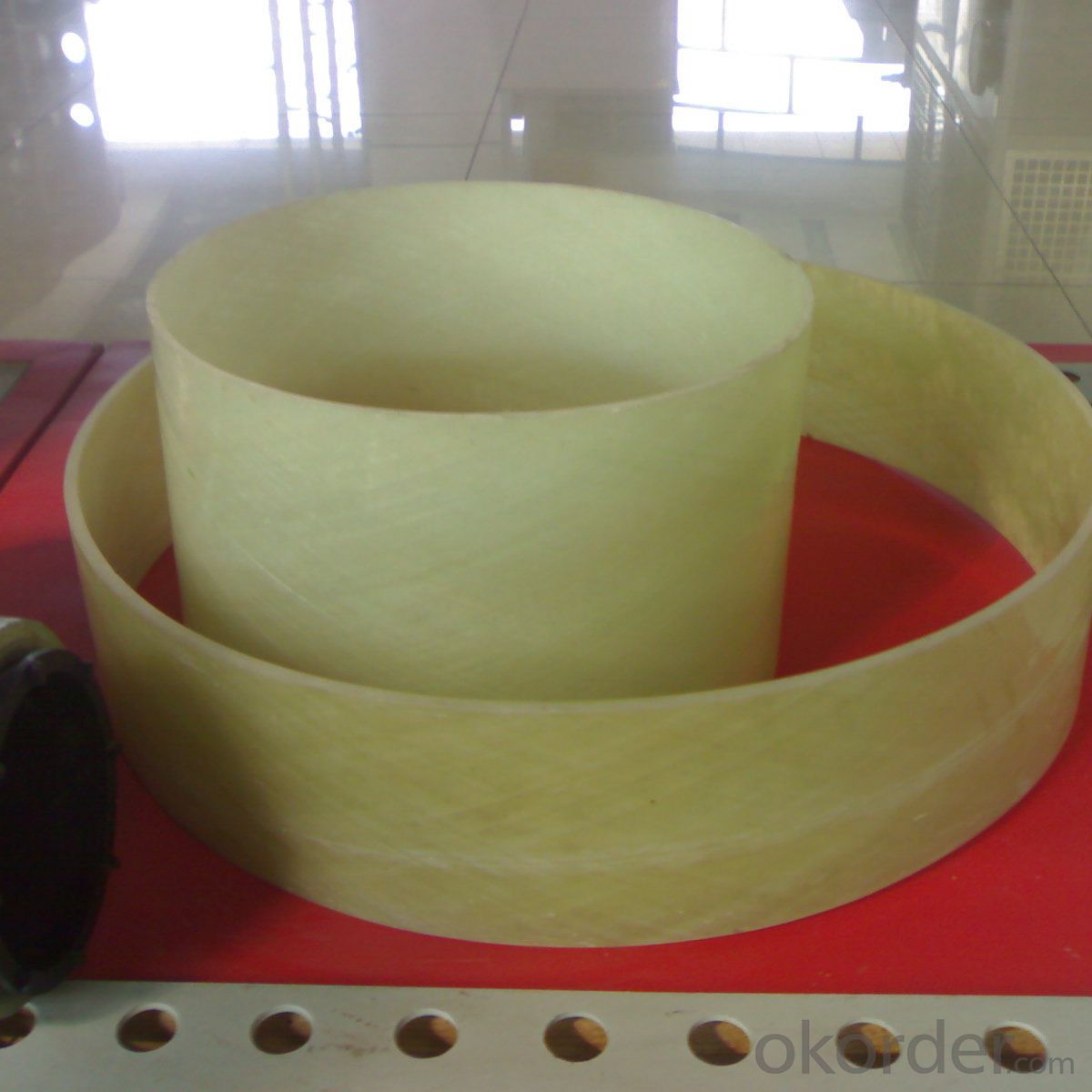

PICTURES