Loading Port:Tianjin

Payment Terms:TT OR LC

Min Order Qty:500 m

Supply Capability:60000 m/month

PRODUCT DESCRIPTION

Fiberglass/ Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity.

Products in the ultralow temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean.Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

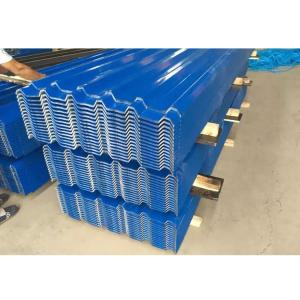

PICTURES