Loading Port:Shanghai

Payment Terms:TT OR LC

Min Order Qty:1 unit

Supply Capability:5 unit/month

Product Description:

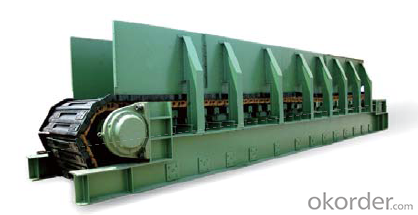

The BWZ Apron Feeder is mainly applied to the cement industry as a hopper to primary crusher for the continuous and uniform feeding purposes and can also be used for short-range transportation of granularity and a large proportion of material, can be horizontally mounted, but also can be tilted installation and the maximum inclination are 25 degrees.The BWH Apron Feeder belong to the intermittent feed machines which is used for short-distance transport to the proportion of particle size<1.6 bulk materials; it can be installed horizontally and can also tilt the installation, the largest upward inclination are 20 degrees; The Feeders in the cement, building materials and other departments are widely used.

Main Product Features:

Apron feeder can be divided to heavy type, medium type and light type. apronfeeder is suitable for different size and packing density. According the driving type, apron feeder can also be divided to right drive and left drive. apron feeder is the common equipment for feeding various crushers in mineral dressing plants and cement plants.

Product Specifications:

| Model | Width of Trough Plate (mm) | Center to Center Distance L (m) | Max. Feed Size (mm) | Capacity (t/h) | Motor Power (kw) |

| Heavy Duty Apron Feeder | |||||

| BWZ1200-L | 1200 | 6-20 | <600< td=""> | 100-200 | 15-22 |

| BWZ1500-L | 1500 | 6-20 | <800< td=""> | 200-270 | 22-30 |

| BWZ1600-L | 1600 | 6-20 | <800< td=""> | 270-330 | 30-45 |

| BWZ1800-L | 1800 | 8-20 | <900< td=""> | 500 | 37-45 |

| BWZ2000-L | 2000 | 8-20 | <1000< td=""> | 700 | 45-75 |

| BWZ2200-L | 2200 | 8-20 | <1200< td=""> | 800 | 45-75 |

| BWZ2300-L | 2300 | 8-20 | <1500< td=""> | 850 | 45-90 |

| BWZ2400-L | 2400 | 10-20 | <1600< td=""> | 900 | 2×37(45) |

| BWZ2500-L | 2500 | 10-20 | <1800< td=""> | 1000 | 2×45(55) |

| Medium Apron Feeder | |||||

| BWH800-L | 800 | 3-15 | <350< td=""> | 0.2-75 | 2.2 |

| BWH1000-L | 1000 | 3-18 | <600< td=""> | 18-200 | 5.5-18.5 |

| BWH1200-L | 1200 | 4-20 | <600< td=""> | 30-220 | 11-18.5 |

| BWH1250-L | 1250 | 4-20 | <800< td=""> | 40-250 | 11 |

| BWH1400-L | 1400 | 5-20 | <900< td=""> | 80-280 | 22 |

| BWH1500-L | 1500 | 5-20 | <900< td=""> | 80-300 | 22-30 |

| BWH1600-L | 1600 | 6-20 | <900< td=""> | 100-320 | 22 |

| BWH1800-L | 1800 | 6-20 | <970< td=""> | 100-350 | 22-55 |

| BWH2000-L | 2000 | 8-20 | <1500< td=""> | 300-800 | 45 |

| BWH2200-L | 2200 | 8-20 | <1500< td=""> | 300-820 | 45 |

| BWH2300-L | 2300 | 8-20 | <1500< td=""> | 500-900 | 45 |

| BWH2400-L | 2400 | 8-20 | <1500< td=""> | 500-1000 | 45 |

| BWH2500-L | 2500 | 10-20 | <1500< td=""> | 500-1250 | 45 |

FAQ:

Q1: How to confirm that your crushers could be used in our site?

A1: We have been providing crushers for more than ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 15-30 workdays.

Q4: If we can produce some crushers according to customers request?

A4: Yes, we can produce crushers according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.